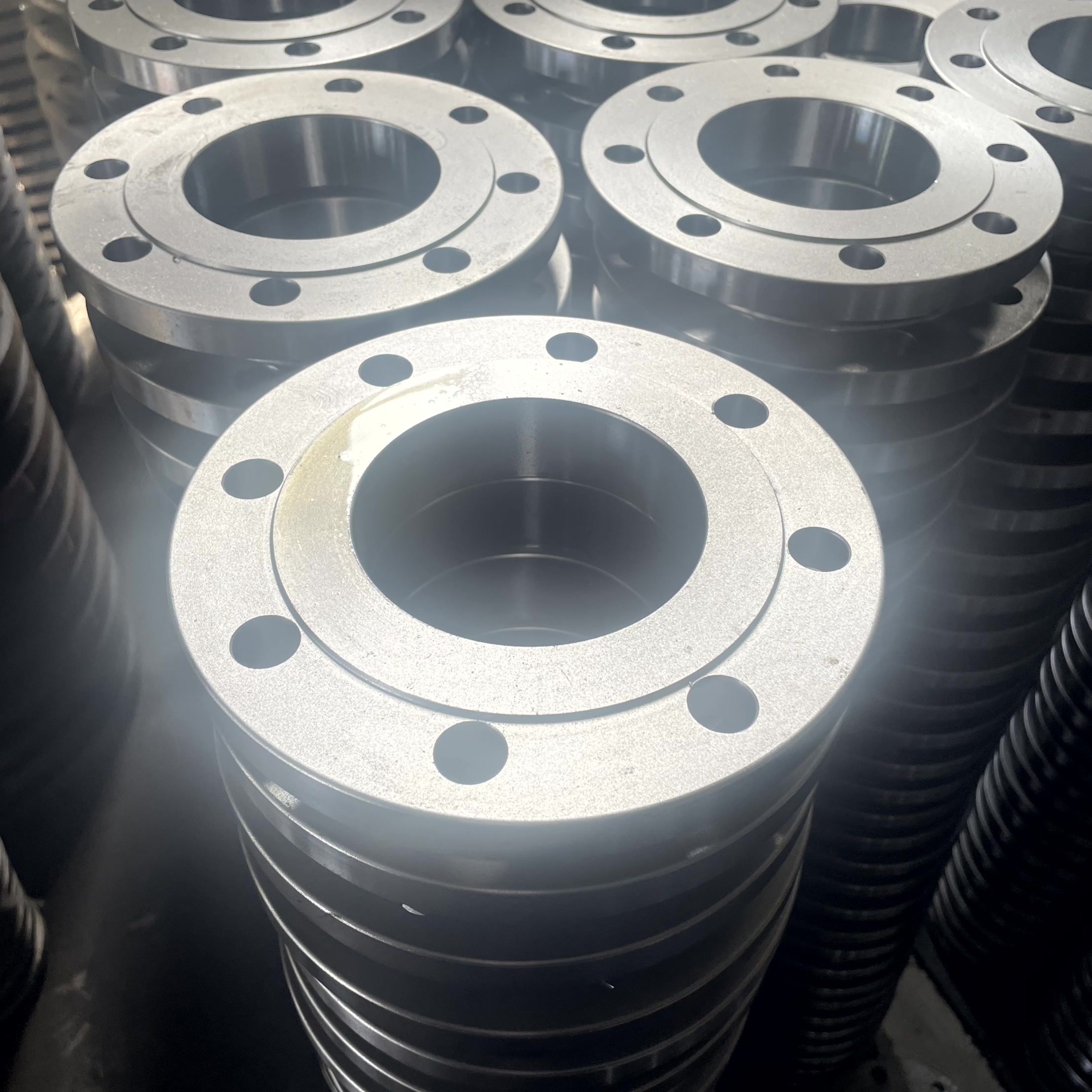

These 304/304L Stainless Steel flanges are engineered for high-integrity sealing and pressure vessel termination. Specifically designed for the 10" to 48" (DN250 – DN1200) range, our forging process ensures grain structure refinement, providing superior resistance to intergranular corrosion and mechanical fatigue in high-pressure headers and distribution manifolds.

1. Technical Specifications

| Parameter | Specification Details |

| Material Grades | ASTM A182 F304/304L (Dual Certified), F316/316L, Duplex S31803 |

| Size Range | NPS 1/2" to 48" (DN15 – DN1200) |

| Pressure Ratings | ASME Class 150, 300, 600, 900, 1500, 2500; PN6 to PN100 |

| Dimensional Stds | ASME B16.5 (up to 24"), ASME B16.47 Series A/B (26"+), EN 1092-1, DIN |

| Facing | Raised Face (RF) 125-250 AARH, Flat Face (FF), Ring Type Joint (RTJ) |

| Manufacturing | Forged, Heat Treated, and CNC Machined |

2. Engineering Advantages

-

Blind Flange Geometry: Designed for the termination of piping systems and pressure vessel openings. The solid forged disc is calculated to withstand significant bolt-load and internal pressure stresses without deformation.

-

Threaded Options (NPT/BSPT): Ideal for explosive environments where welding is prohibited (Hot Work restrictions) or for systems requiring frequent disassembly in low-pressure applications.

-

Corrosion Resistance: The low-carbon 304L variant prevents carbide precipitation during any secondary welding processes, maintaining the integrity of the heat-affected zone (HAZ).

3. Quality Assurance & Compliance

We operate under a rigorous QC framework to ensure zero-leak performance in critical infrastructure:

-

Material Verification: Positive Material Identification (PMI) and Spectrographic Analysis.

-

Non-Destructive Testing (NDT): Ultrasonic (UT) and Radiographic (RT) testing available for high-pressure Class 900+ specifications.

-

Dimensional Tolerance: Strict adherence to ASME B16.5 tolerances for bolt hole alignment, thickness, and facing concentricity.

-

Certification: Full MTRs (Material Test Reports) provided per EN 10204 3.1.

4. Application Environments

-

Midstream Oil & Gas: Pig launcher/receiver closures.

-

Cryogenic Service: 304 SS maintains toughness at sub-zero temperatures.

-

Water Infrastructure: Desalination and high-capacity treatment manifolds.

-

Chemical Processing: Reactive media containment where 300-series stability is required.

Logistics & Procurement

-

Origin: Hebei Cangtie Industrial Co., Ltd (Cangzhou, China).

-

Lead Times: 3–5 days (Ex-stock) | 10–25 days (Custom Forging/Large Diameter).

-

Packaging: Export-grade seaworthy wooden cases with moisture-barrier lining.