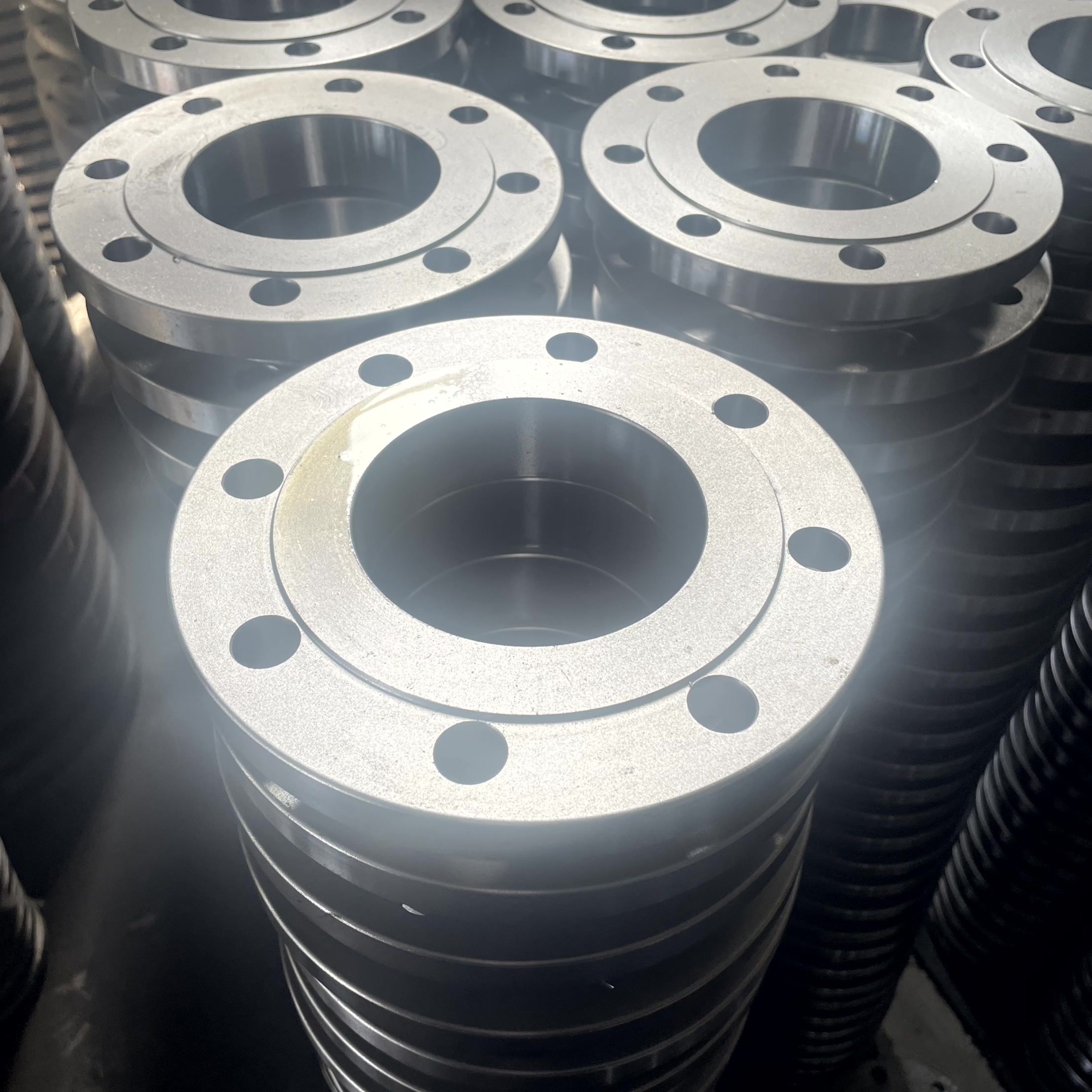

Specifications: PN10 / PN16 | Material: Stainless Steel (304/316L) & Carbon Steel

DIN Threaded Flanges (also known as Screwed Flanges) are designed to be joined to the piping system by threading the pipe into the flange. This design is highly efficient for applications where welding is hazardous, restricted, or technically impractical.

1. Key Features & Benefits

-

No Welding Required: Ideal for volatile environments (oil & gas) or areas where "hot work" permits are difficult to obtain.

-

Ease of Maintenance: Allows for quick assembly and disassembly for routine inspection or cleaning of the pipeline.

-

High Corrosion Resistance: Our stainless steel variants (316L) offer superior protection against acidic and saline environments.

-

Standard Compliance: Manufactured strictly according to DIN standards, ensuring total interchangeability with other German-standard components.

2. Technical Specifications

| Feature | Details |

| Standards | DIN 2565, DIN 2566, DIN 2567 |

| Pressure Rating | PN6, PN10, PN16, PN25, PN40 |

| Size Range | DN15 to DN150 (1/2" to 6") |

| Facing | Raised Face (RF) or Flat Face (FF) |

| Thread Types | BSP (Parallel), BSPT (Tapered), or NPT (per request) |

3. Premium Material Options

Stainless Steel (SS304 / SS316L)

-

SS304: The standard "18/8" stainless steel. Excellent for water treatment, food processing, and general industrial use.

-

SS316L: Enhanced with Molybdenum for superior resistance to pitting and crevice corrosion. Ideal for marine and chemical industries.

Carbon Steel

-

Grades: S235JR, P250GH, C22.8, ASTM A105.

-

Surface Treatment: Available with Anti-rust oil, Clear Vanish, Electro-galvanized, or Hot-dip Galvanized (HDG) for maximum durability.

4. Typical Applications

-

HVAC Systems: Chilled water and heating loops.

-

Fire Protection: Connecting sprinklers and standpipes.

-

Chemical Processing: Transporting non-critical corrosive fluids.

-

Gas Utilities: Low-pressure gas distribution where welding might pose a fire risk.

5. Why Choose Our Flanges?

-

Thread Precision: Every flange is gauged to ensure perfect thread engagement and zero leakage.

-

Full Traceability: Material Test Reports (MTRs) are provided for every batch, detailing chemical composition and mechanical properties.

-

Durable Finishing: Carbon steel flanges undergo premium coating processes to prevent oxidation during transit and storage.

Ready to move forward?

I can help you generate a Technical Quotation Template or a Comparison Table between SS304 and SS316L properties to assist your customers in choosing the right material. Would you like me to prepare that for you?