Product Overview

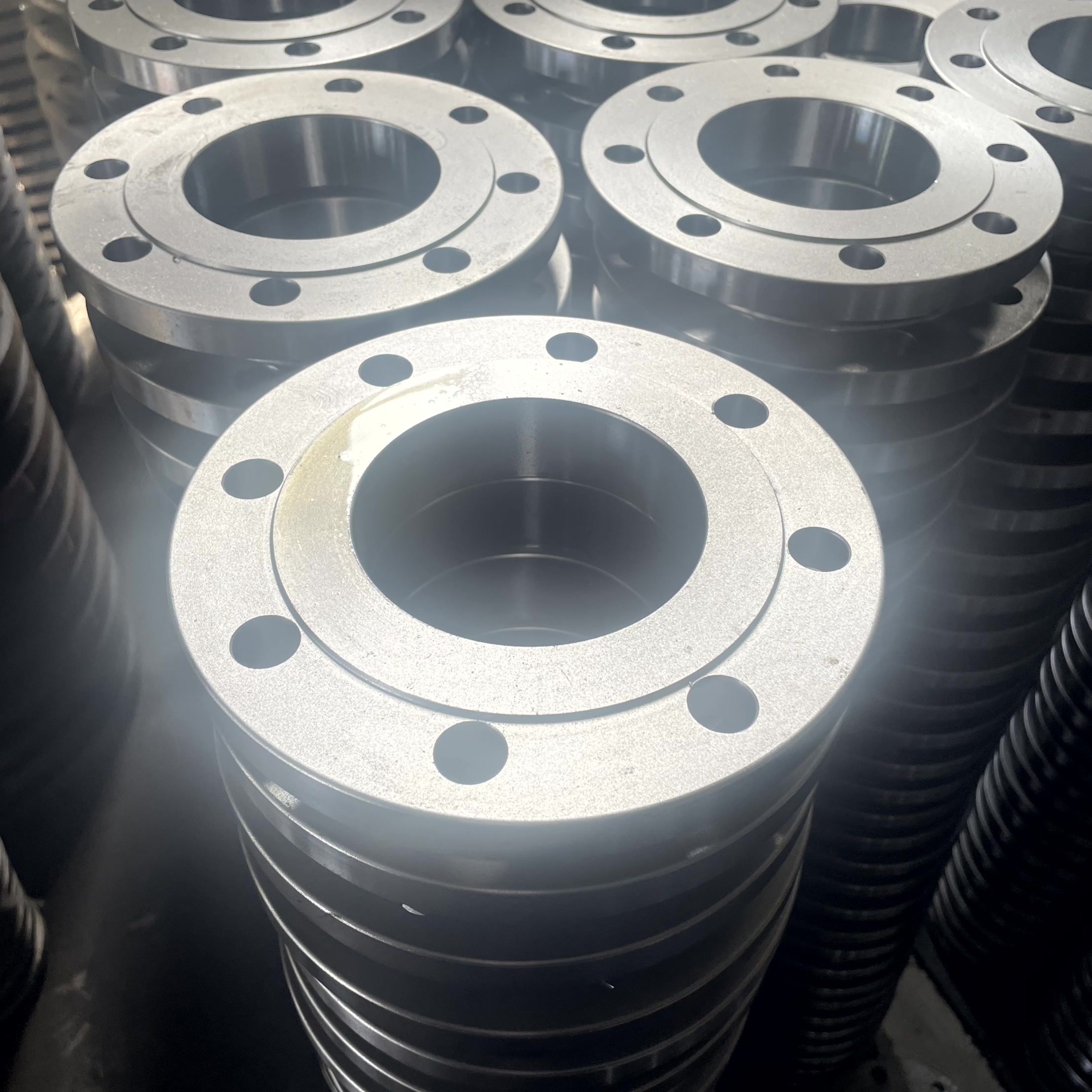

The DN150 (6") Threaded Forged Flange from Hebei Cangtie Industrial Co., Ltd is the definitive choice for high-stakes environments where corrosion resistance and structural integrity are non-negotiable.

Crafted from dual-certified 316/316L stainless steel, this flange provides superior resistance to pitting and crevice corrosion in chloride-rich environments—making it ideal for offshore, chemical processing, and pharmaceutical applications. The 6-inch (DN150) size is engineered to maintain a perfect seal under mechanical stress, featuring a Raised Face (RF) with precision-machined serrations to ensure maximum gasket adhesion.

Why Choose Our 316/316L Forged Flanges?

-

Dual Grade Excellence: Our material meets both 316 and 316L specifications, offering the high strength of 316 and the low-carbon weldability/intergranular corrosion resistance of 316L.

-

Superior Forging Process: Unlike cast flanges, our forging process ensures a refined grain structure, eliminating porosity and ensuring the flange can withstand pressure surges up to Class 600 and beyond.

-

Micro-Finished Threads: Threads are CNC-cut to ASME B1.20.1 standards, ensuring smooth galling-free installation and a leak-proof fit with Schedule 40/80 piping.

-

Serrated Spiral Finish: The Raised Face (RF) features a standardized serrated finish (125-250 AARH) to prevent "gasket walk" and ensure a long-term seal.

Technical Specifications

| Specification | Details |

| Material Grade | ASTM A182 F316/316L (Dual Certified) |

| Nominal Size | DN150 / 6 Inch |

| Standard | ANSI / ASME B16.5 |

| Pressure Ratings | Class 150, 300, 600, 900, 1500 |

| Facing | Raised Face (RF) / Ring Type Joint (RTJ) |

| Thread Standards | NPT (National Pipe Thread) / BSPT |

| Surface Treatment | Pickled & Passivated / Bright Polished |

Core Industry Applications

-

Marine & Offshore: Saltwater cooling systems and desalination units.

-

Chemical & Petrochemical: Handling of corrosive acids, chlorides, and solvents.

-

Food & Beverage: Hygienic piping requiring high-grade stainless steel for easy cleaning.

-

Pharmaceutical: Clean-room grade piping systems where purity is critical.

The Hebei Cangtie Advantage

1. Material Integrity Guaranteed

We provide a 3.1 Mill Test Certificate (MTC) with every order, detailing the exact chemical composition (Cr, Ni, Mo content) and mechanical properties of your 316L flange.

2. Precision Manufacturing

Located in the Yanshan industrial hub, our facility uses advanced CNC machining centers to ensure that the DN150 dimensions are accurate to within microns, ensuring perfect alignment on-site.

3. Global Logistics Excellence

-

Fast-Track Shipping: 3–5 days for in-stock DN150 flanges.

-

Custom Packaging: Plywood cases or pallets with individual protective caps for threads to prevent transit damage.

Get a Quote Today

Need technical data or a bulk price list for your next project? Our team is ready to assist.

-

Contact Person: Hudson Liu

-

Mobile / WhatsApp: +86 157 3370 8805

-

Email: hudson@cangtiepipe.com

-

Website: https://ctflange.com/

-

Factory: Yanshan Economic Development Zone, Cangzhou, Hebei, China.