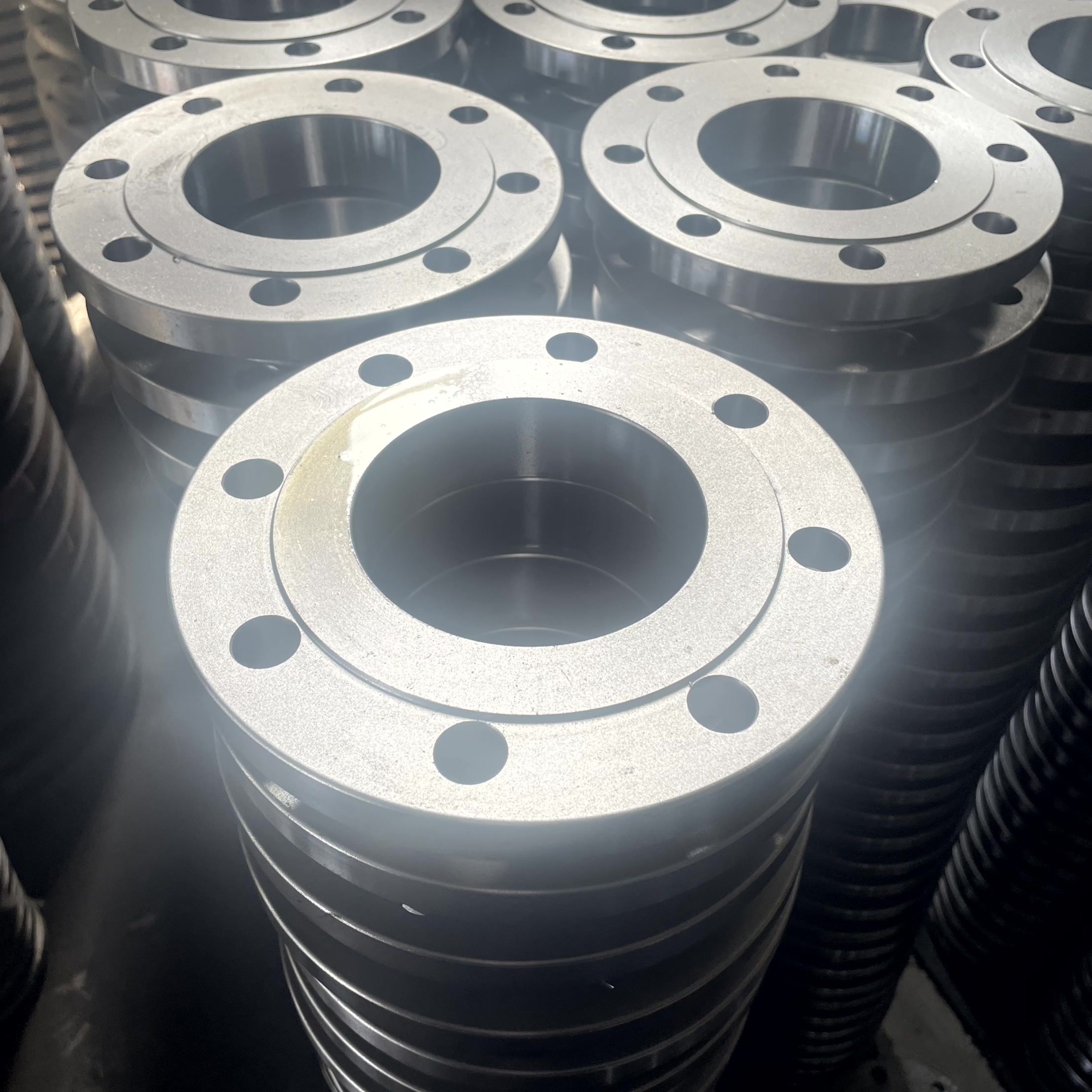

Hebei Cangtie Industrial Co., Ltd offers a versatile range of Threaded Screwed Flanges, precision-forged to meet the rigorous demands of modern industrial piping. Our flanges are available in ASTM A105N (Normalized) for superior toughness and Stainless Steel 304/316 for maximum corrosion resistance.

Designed with a Raised Face (RF) and a forged hub that mimics the strength of a Butt Weld (BW) fitting, these flanges provide a high-pressure seal without the need for on-site welding. This makes them the premier choice for hazardous environments where "hot work" is restricted, or for systems requiring frequent disassembly.

Core Material Advantages

-

ASTM A105N (Normalized): Unlike standard A105, our A105N undergoes a normalization heat treatment to refine the grain structure, providing enhanced impact resistance and superior performance in critical pressure applications.

-

SS304/316/316L: Our stainless steel variants offer exceptional resistance to oxidation and chemical erosion, with 316L providing extra protection against intergranular corrosion after machining.

-

Precision Threading: All threads are CNC-machined to ASME B1.20.1 (NPT) or ISO 7-1 (BSPT), ensuring deep engagement and a leak-proof mechanical joint.

Technical Specifications

| Feature | Specification Details |

| Material Grades |

Carbon Steel: ASTM A105N, A350 LF2 Stainless Steel: F304/304L, F316/316L |

| Standard | ASME B16.5, ANSI, DIN, JIS, EN1092-1 |

| Size Range | ½″ – 24″ (DN15 – DN600) |

| Pressure Class | Class 150, 300, 600, 900, 1500, 2500 |

| Facing Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Surface Treatment | Anti-rust Oil, Black Paint, Hot-Dip Galvanizing, or Passivation |

Advanced Engineering Features

-

Forged Structural Integrity: 100% forged bodies ensure no internal defects or air holes, unlike cheaper cast alternatives.

-

RF Serrated Finish: The Raised Face features a spiral serrated finish to maximize gasket friction and prevent blowout under pressure.

-

Ease of Maintenance: Ideal for small-diameter piping where welding is impractical or where the system must be dismantled for cleaning or inspection.

Why Hebei Cangtie is Your Best Choice?

1. Specialized Manufacturing Hub

Located in Cangzhou, Hebei—China’s piping capital—we leverage a decade of forging expertise to deliver products that meet international safety standards (ASME, ANSI, DIN).

2. Quality Assured & Traceable

-

MTC 3.1 Provided: Full traceability with Mill Test Certificates.

-

NDT Testing: Ultrasonic and Magnetic Particle testing available upon request.

-

Thread Inspection: Every flange is checked with calibrated Go/No-Go gauges.

3. Global OEM & Customization

We provide custom markings, specific coatings (like PTFE or high-zinc epoxy), and tailored packaging for international sea and air freight.

Consult Our Sales Team

Ready to streamline your piping project? Contact Hudson Liu for a technical consultation and competitive pricing.

-

Contact Person: Hudson Liu

-

Mobile / WhatsApp: +86 157 3370 8805

-

Email: hudson@cangtiepipe.com

-

Website: https://ctflange.com/

-

Factory Address: Yanshan Economic Development Zone, Cangzhou City, Hebei Province, China