Product Overview

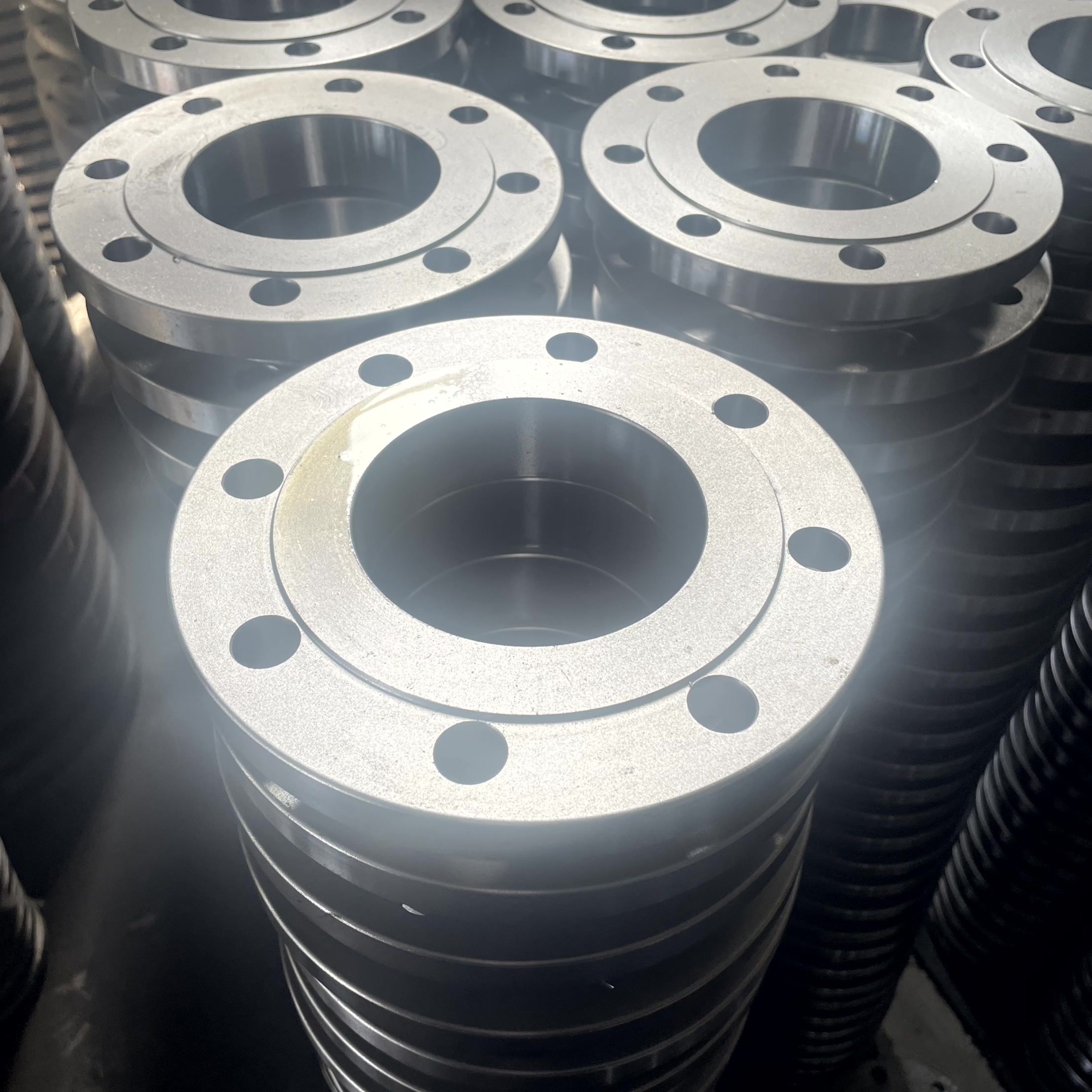

In the power generation industry, there is zero margin for error. Hebei Cangtie Industrial Co., Ltd provides premium ASTM A105 Forged Steel Threaded Flanges specifically engineered for the extreme thermal and mechanical stresses of power plant piping.

Our A105 flanges undergo a rigorous closed-die forging process, which eliminates internal voids and creates a dense, uniform grain structure. This ensures the flange can handle rapid pressure fluctuations and high-temperature steam cycles without compromise. The precision-cut threads allow for a secure, weld-free connection—perfect for areas where hot work is restricted or for rapid maintenance in auxiliary power systems.

Why A105 Forged Flanges for Power Plants?

-

Extreme Temperature Resilience: Optimized for service in ambient to high-temperature conditions, meeting the strict safety protocols of boiler and turbine environments.

-

Zero-Leak Thread Precision: Our threads (NPT/BSPT) are machined to ASME B1.20.1 standards, ensuring a gas-tight seal even under vibration.

-

Enhanced Fatigue Resistance: The forging process increases the material's yield strength, making it far superior to cast alternatives in high-vibration power environments.

-

Superior Sealing Faces: Available in Raised Face (RF) with serrated finishes (125-250 AARH) to maximize gasket "bite" and prevent blowout.

Technical Specifications

| Feature | Specification Details |

| Material | ASTM A105 Carbon Steel (High Temp Service) |

| Manufacturing | Forged, Heat Treated (Normalized), CNC Machined |

| Standard | ASME/ANSI B16.5, MSS-SP-44, BS 3293 |

| Pressure Class | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Size Range | ½″ – 24″ (DN15 – DN600) |

| Thread Type | NPT, BSPT, or Custom Tapered Threads |

| Surface Finish | Rust-preventative Oil, Hot-Dip Galvanized, or Zinc Plated |

Technical Note: For sub-zero temperature power applications, we also provide ASTM A350 LF2 low-temperature carbon steel options.

Key Power Plant Applications

-

High-Pressure Steam Lines: Reliable connections for boiler feed-water and steam distribution.

-

Auxiliary Cooling Systems: Secure piping for heat exchangers and condensers.

-

Fuel Handling: Safe transport of oil and gas fuels to burners.

-

Ash Handling & Water Treatment: Durable joints for abrasive and chemical-laden drainage.

Hebei Cangtie: Your Certified Manufacturing Partner

1. Material Traceability: Every flange is shipped with a 3.1 Mill Test Certificate (MTC), ensuring chemistry and physical properties meet ASTM A105 requirements.

2. Advanced CNC Machining: We use high-precision CNC lathes to ensure thread concentricity and perfect perpendicularity to the flange face.

3. Strict Quality Gates: * PMI Testing: Material verification.

-

Thread Gauging: Every thread is checked with Go/No-Go gauges.

-

Visual Inspection: Zero-defect policy for surface finish and marking.

Contact Our Power Industry Specialists

We understand the urgency of power plant maintenance and project deadlines. Contact us for a rapid quote and technical support.

-

Contact Person: Hudson Liu

-

Mobile / WhatsApp: +86 157 3370 8805

-

Email: hudson@cangtiepipe.com

-

Website: https://ctflange.com/

-

Factory: Yanshan Economic Development Zone, Cangzhou, Hebei, China.