Hebei Cangtie Industrial Co., Ltd specializes in manufacturing high-precision Stainless Steel Stub Ends designed for seamless integration with Lap Joint Flanges. Our stub ends are engineered to ASME B16.9 standards, providing a cost-effective and flexible connection solution for piping systems that require frequent cleaning, inspection, or rapid disassembly.

By using a stub end with a carbon steel lap joint flange, you achieve the corrosion resistance of stainless steel at the wetted surface while significantly reducing overall material costs. Whether you need Long Pattern for standard applications or Short Pattern for tight spaces, our fittings ensure a perfect, leak-proof fit.

Core Features & Technical Advantages

-

Superior Corrosion Resistance: Available in SS304/L, SS316/L, and SS321, ideal for chemical processing and marine environments.

-

Dual Manufacturing Processes: * Seamless Stub Ends: Cold-pressed from high-quality tubes for high-pressure integrity.

-

Welded Stub Ends: Precision-welded and X-ray tested for large-diameter requirements.

-

-

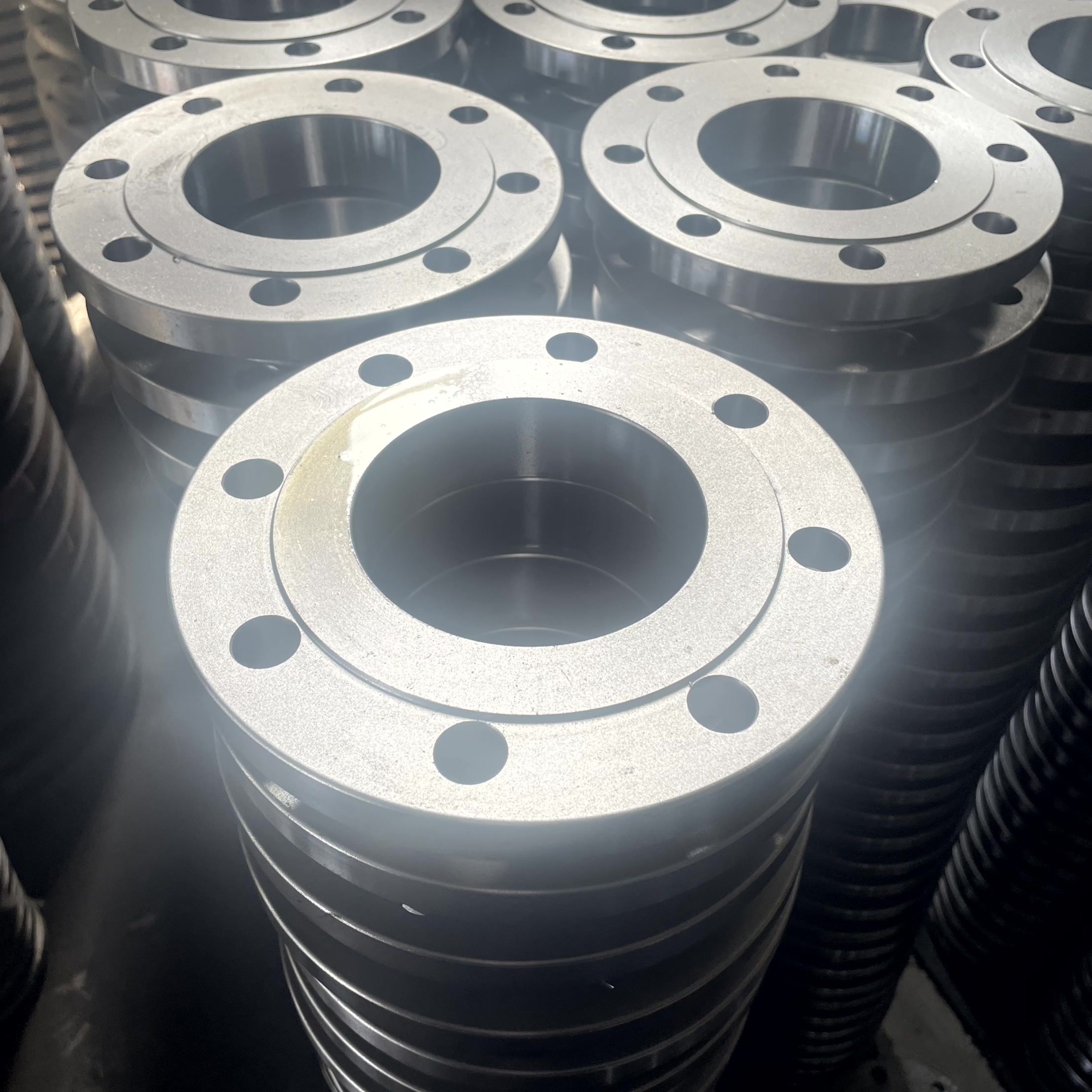

Perfect Gasket Sealing: The lap joint face is CNC-machined to ensure a flat, smooth surface (RF) that matches perfectly with gaskets to prevent bypass leakage.

-

Full Standard Compliance: Manufactured and tested strictly according to ASME B16.9 and ASTM A403 specifications.

Product Specifications

| Stub End Type | Material Grade Options | Size Range | Wall Thickness |

| Long Pattern | WP304/L, WP316/L, WP321 | ½″ – 24″ (DN15-600) | SCH 10S to SCH 80S |

| Short Pattern | WP304/L, WP316/L, A234 WPB | ½″ – 24″ (DN15-600) | SCH 5S to SCH XXS |

| Seamless Type | Stainless & Carbon Steel | ½″ – 12″ (DN15-300) | According to ASME B16.9 |

| Welded Type | SS304/316, Alloy Steel | 14″ – 48″ (DN350-1200) | Custom Wall Thickness |

Key Applications

Our Stub Ends are the preferred choice for industries where maintenance flexibility is critical:

-

Petrochemical & Refining: For pipelines requiring periodic internal cleaning.

-

Water Treatment: Desalination and wastewater management systems.

-

Food & Beverage: Sanitary piping where easy disassembly is required for hygiene.

-

Marine & Shipbuilding: Corrosion-resistant connections in ballast and cooling systems.

Why Source from Hebei Cangtie?

1. 100% Quality Traceability

Every Stub End is laser-marked with the heat number, size, and material grade. We provide EN 10204 3.1 Mill Test Certificates to guarantee chemical and mechanical compliance.

2. Precision Machining & Finishing

We utilize advanced Tumble Joint and Stamping techniques to ensure uniform wall thickness at the radius—the most critical point of a stub end—preventing stress concentration.

3. Global Supply Logistics

-

Fast Lead Times: Stocked standard sizes ship within 3–5 working days.

-

Protection: Ends are beveled to ANSI B16.25 and protected with plastic caps to ensure they arrive job-site ready.

Contact Us for a Quick Quote

Our technical team is ready to provide the most cost-effective piping solutions for your project.

-

Contact Person: Hudson Liu

-

Mobile / WhatsApp: +86 157 3370 8805

-

Email: hudson@cangtiepipe.com

-

Website: https://ctflange.com/

-

Factory Address: Yanshan Economic Development Zone, Cangzhou, Hebei, China.