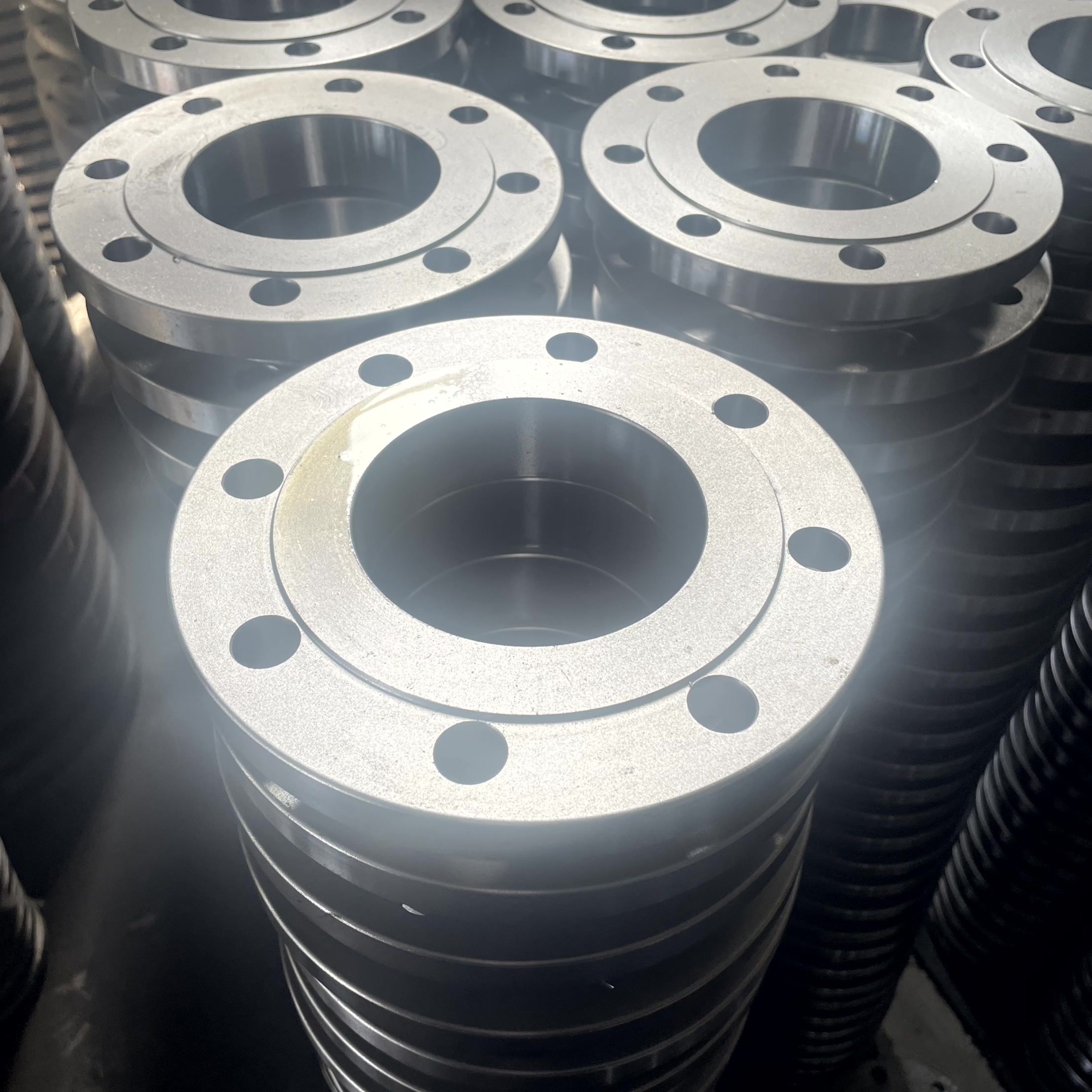

Size: DN250 | Material: Stainless Steel SS304/316L

The DIN 86029 standard specifies flanges used primarily in shipbuilding and marine exhaust/water systems. As a Slip-On (Hubbed) type, it is designed to slide over the pipe and be welded both internally and externally to provide sufficient strength and prevent leakage.

1. Product Overview

The DN250 PN10 variant is a heavy-duty marine component designed for large-bore piping. Its "Slip-On" design simplifies alignment, making it a preferred choice for shipyard installations where space and maneuverability can be challenging.

2. Technical Specifications (DN250 / PN10)

| Parameter | Specification (DIN 86029) |

| Nominal Diameter | DN250 (10 Inch) |

| Pressure Rating | PN10 (10 Bar) |

| Outer Diameter (D) | 395 mm |

| Bolt Circle Diameter (K) | 350 mm |

| Number of Bolt Holes | 12 |

| Bolt Hole Diameter (L) | 22 mm |

| Flange Thickness (b) | 26 mm |

| Facing | Type C (Raised Face - RF) |

3. Material Excellence: Stainless Steel

To withstand the harsh, corrosive nature of marine environments, we offer this flange in high-grade stainless steel:

-

SS316L (1.4404): Recommended for seawater-facing applications. The low carbon content prevents sensitization during welding, ensuring maximum corrosion resistance at the weld joints.

-

SS304 (1.4301): Suitable for freshwater systems, sewage treatment, and non-corrosive marine utilities.

4. Key Advantages

-

Marine Certified Design: Specifically engineered to meet the structural requirements of the shipbuilding industry.

-

Raised Face (RF) Sealing: The 2mm raised face concentrates more pressure on a smaller gasket area, ensuring a superior seal at PN10 pressure levels.

-

Ease of Fitment: The slip-on nature allows for slight adjustments in pipe length and easier alignment of bolt holes compared to weld-neck flanges.

-

Superior Durability: High resistance to pitting and crevice corrosion in humid, salty atmospheres.

5. Applications

-

Shipbuilding: Ballast systems, bilge piping, and seawater cooling.

-

Offshore Platforms: Utility piping and firewater systems.

-

Marine Exhausts: Engine room piping and ventilation.

-

Water Treatment: Coastal desalination plants.

6. Quality Assurance

-

Dimension Check: Precise machining of the DN250 bore for a perfect "slip" fit over the pipe.

-

Surface Finish: Smooth, CNC-machined raised face to ensure optimal gasket seating.

-

Documentation: EN 10204 3.1 Mill Test Certificates provided with every shipment.

Would you like to add a "Cross-Standard Reference" to this page?

I can provide a comparison between this DIN 86029 flange and the more common DIN 2576 or EN 1092-1 equivalents to help your customers confirm compatibility. Would you like me to do that?