This is a high-specification industrial component designed for extreme pressure and corrosive environments. Below is a professional product introduction formatted for a technical catalog or a high-end commercial proposal.

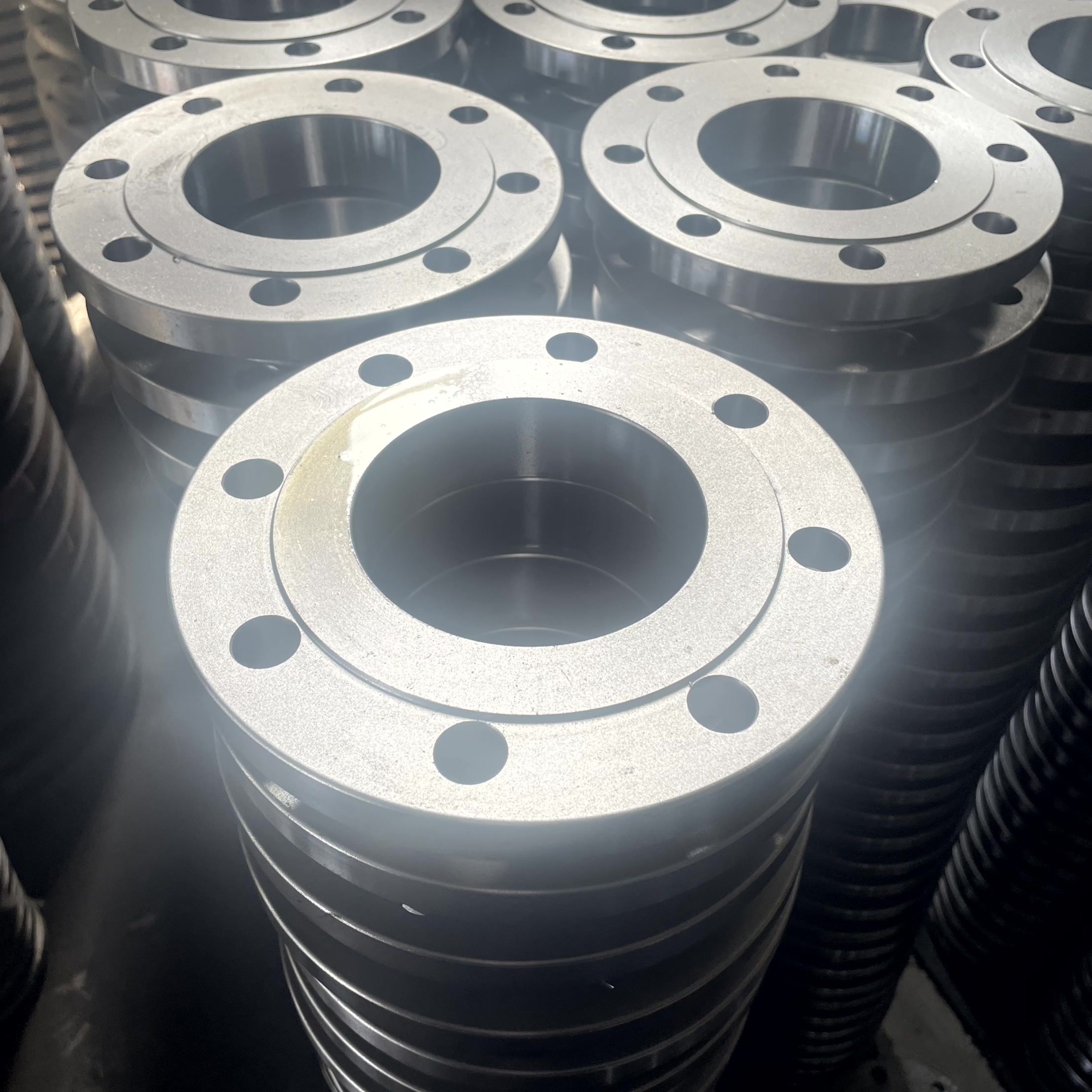

8" Sch60 Weld Neck Flange | Class 600

ASTM A182 F316/316L Dual Grade | ASME B16.5 | RF | NACE MR0175

This 8-inch Weld Neck Flange (WNF) is engineered for high-pressure piping systems where structural integrity and leak prevention are critical. Featuring a long tapered hub, it provides vital reinforcement for applications involving high pressure, sub-zero temperatures, or extreme heat.

1. Key Technical Specifications

| Specification | Details |

| Size / NPS | 8" (DN200) |

| Pressure Class | Class 600 (approx. 100 bar / 1480 psi at ambient) |

| Flange Type | Weld Neck (WNF) |

| Bore / Schedule | Schedule 60 (Matches 8" Sch60 pipe ID) |

| Facing | Raised Face (RF) |

| Material Standard | ASTM A182 F316/316L (Dual Certified) |

| Dimensional Standard | ASME B16.5 |

| Compliance | NACE MR0175 / ISO 15156 (Sour Service) |

2. Material Advantages: F316/316L Dual Grade

By combining the properties of both 316 and 316L, this flange offers the best of both worlds:

-

Corrosion Resistance: The addition of Molybdenum provides excellent resistance to chlorides and pitting, superior to Grade 304.

-

Low Carbon (316L): Prevents carbide precipitation during the welding of the heavy 8" Sch60 neck, ensuring the heat-affected zone remains corrosion-resistant.

-

High Strength (316): Meets the higher mechanical strength requirements of standard 316, making it ideal for Class 600 pressure ratings.

3. Engineering Highlights

-

Superior Stress Distribution: The tapered hub transfers stress from the flange to the pipe, reducing stress concentration at the base of the flange.

-

NACE MR0175 Compliance: Specifically tested and certified for "Sour Service" (H2S environments), preventing sulfide stress cracking.

-

Precision Bore (Sch60): The bore is machined to match the Schedule 60 pipe wall thickness exactly, ensuring smooth fluid flow and minimal turbulence/erosion at the joint.

-

Forged Construction: Forged at high temperatures to ensure a refined grain structure, offering significantly higher impact and fatigue resistance than cast alternatives.

4. Primary Applications

-

Oil & Gas: High-pressure offshore platforms and sour gas processing plants.

-

Petrochemical: Refining processes involving corrosive chemicals at high temperatures.

-

Power Generation: High-pressure steam lines and feedwater systems.

-

Heavy Industrial: Specialized hydraulic and high-pressure fluid transfer.

5. Quality & Documentation

Every flange undergoes rigorous quality control to meet global safety standards:

-

Full Traceability: Heat number stamped on the flange rim.

-

Certification: EN 10204 3.1 Mill Test Certificate (MTC) included.

-

Testing: Ultrasonic Testing (UT), Positive Material Identification (PMI), and NACE-compliant hardness testing.

Would you like me to prepare a "Technical Data Sheet" for this specific item?

I can include the exact dimensions (Outer Diameter, Bolt Circle, Hub Height) and the specific chemical composition limits for F316/316L. Would that be helpful for your technical submittal?