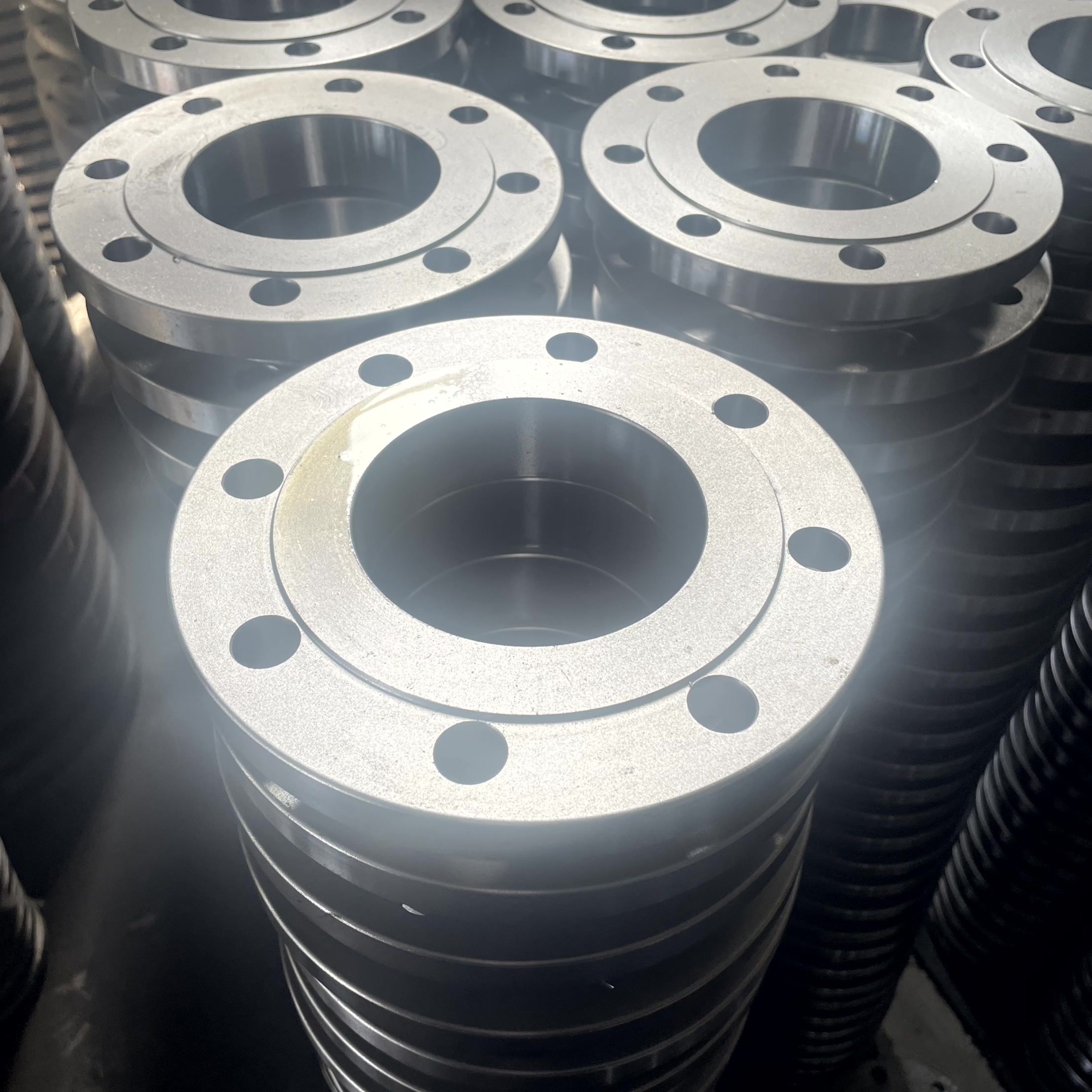

High-Quality ASME B16.5 Weld Neck Flange

Material: ASTM A105N Carbon Steel | Forged Strength

The Weld Neck Flange (WNF) is the premium choice for high-pressure, high-temperature, and fluctuating stress environments. Characterized by a long tapered hub that is butt-welded to the pipe, this design ensures a smooth transition of stress and minimizes turbulence within the pipeline.

1. Material Specification: The "N" Advantage (ASTM A105N)

Our flanges are manufactured from ASTM A105N, where the "N" stands for Normalized heat treatment.

-

Refined Grain Structure: Normalizing involves heating the steel to a specific temperature and cooling it in still air, which uniformizes the grain structure.

-

Enhanced Toughness: Compared to standard A105, A105N provides superior impact strength and ductility, especially in lower-temperature service.

-

Extended Lifespan: Better resistance to fatigue and internal pressure surges.

2. Engineering Excellence

-

Structural Integrity: The tapered hub moves the stress concentration away from the flange base to the pipe itself, providing vital reinforcement.

-

Butt-Weld Connection: Allows for easy radiography (X-ray) inspection of the weld seam, ensuring 100% safety compliance for critical applications.

-

Bore Matching: We precision-machine the flange bore to match your specific pipe schedule (e.g., Sch 40, Sch 80, Sch XS, Sch 160), preventing internal flow restrictions.

3. Technical Parameters

| Feature | Details |

| Standard | ASME B16.5 (Pipe Flanges and Flanged Fittings) |

| Size Range | 1/2" to 24" (Larger sizes available per ASME B16.47) |

| Pressure Class | Class 150, 300, 400, 600, 900, 1500, 2500 |

| Facing | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Surface Coating | Anti-rust oil, Black Paint, Yellow Paint, or Hot-Dip Galvanized |

4. Typical Applications

Due to its robust design, the A105N Weld Neck flange is the industry standard for:

-

Oil & Gas Refineries: High-pressure crude oil and gas transmission lines.

-

Steam Systems: High-temperature boiler piping and power plant infrastructure.

-

Chemical Processing: Handling non-corrosive fluids at elevated pressures.

-

Critical Utilities: Main water and gas trunklines requiring maximum safety.

5. Why Choose Our Forged Flanges?

-

Strict Forging Ratio: We ensure a high forging ratio to eliminate internal porosity and defects common in cast products.

-

CNC Precision: Serrated spiral finishes (125-250 AARH) on the flange face ensure optimal gasket "grip" and a leak-proof seal.

-

Comprehensive Certification: Every shipment is accompanied by an EN 10204 3.1 MTC, detailing chemical analysis, tensile strength, hardness, and impact test results.

Do you need to match these flanges with specific pipes?

I can provide you with a Dimensional Chart for Class 150 vs. Class 300 to help you confirm the bolt hole patterns for your project. Would you like me to generate that for you?