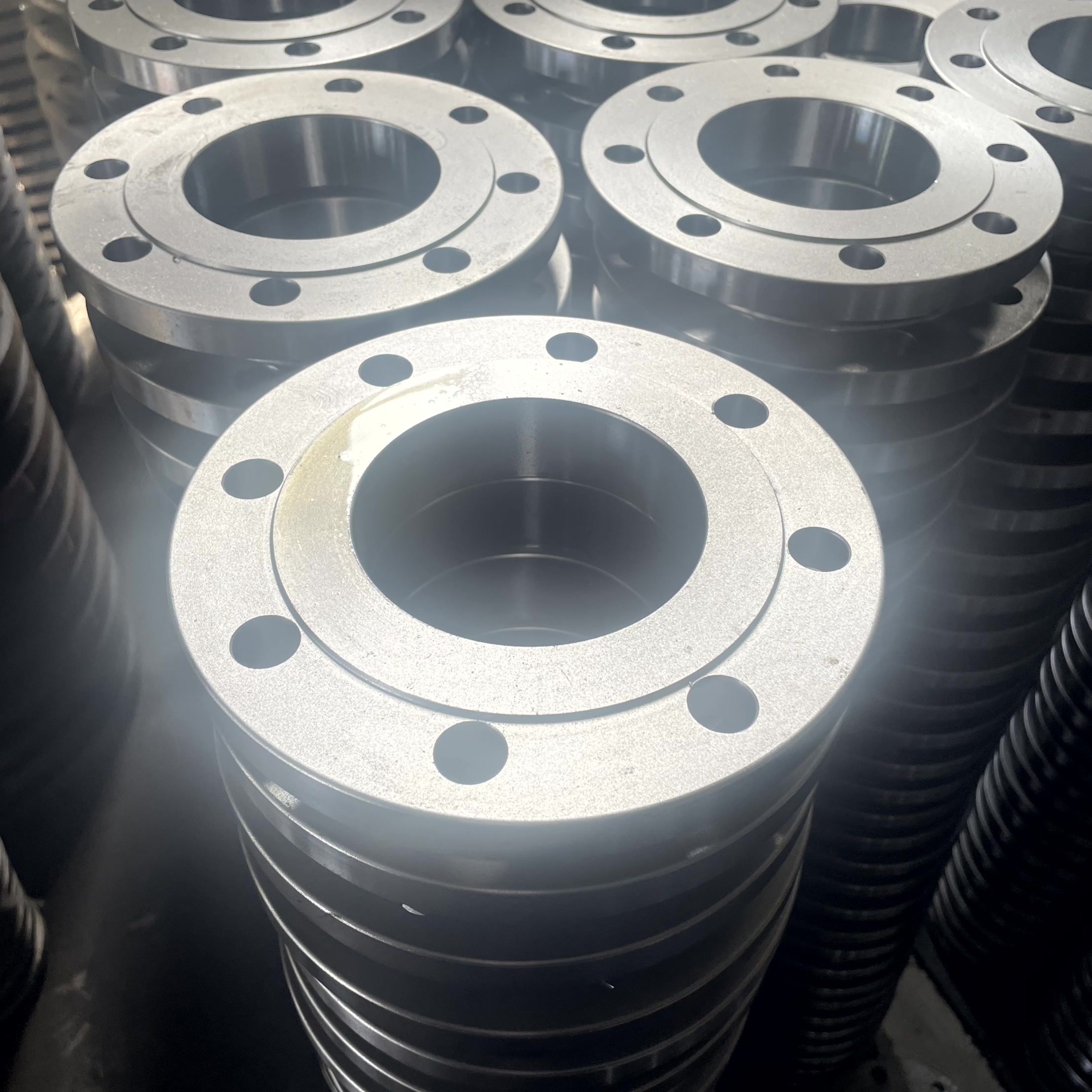

Product Description

Our 2-inch Blind Flange is precision forged from ASTM A182 Grade F316/316L dual-grade stainless steel, ensuring exceptional corrosion resistance and mechanical strength. Designed to meet the ASME B16.5 standard, this flange features a raised face (RF) sealing surface for optimal gasket placement and a reliable, leak-proof connection.

Rated for Class 600 pressure, this blind flange is ideal for demanding industrial applications such as chemical processing, oil & gas, marine, and water treatment industries. Its robust forged construction guarantees long-term durability, making it suitable for high-pressure and high-temperature environments.

The blind flange allows secure pipeline isolation for maintenance or system modifications without flow disruption, providing operational safety and flexibility.

Product Specifications Table

| Product Type | Material | Pressure Class | Standards | Size Range (Nominal Diameter) | Sealing Surface | Surface Finish | Installation Method |

|---|---|---|---|---|---|---|---|

| Blind Flange | Stainless Steel 304 / 304L | ANSI Class 150 – 2500 lbs | ANSI B16.5, ASME B16.47 | DN15 – DN1200 (½" – 48") | Raised Face (RF) | Mirror Polish, Matt, Sand-Blasted | Welding / Bolted Connection |

| Blind Flange | Stainless Steel 316 / 316L | DIN PN6 – PN100 | DIN 2635, EN1092-1 | DN15 – DN1200 (½" – 48") | Raised Face (RF) | Mirror Polish, Matt, Sand-Blasted | Welding / Bolted Connection |

| Blind Flange | Duplex Steel (ASTM A182 S31803, S32205) | ANSI Class 150 – 2500 lbs | ANSI, ASTM, ASME | DN15 – DN1200 (½" – 48") | Raised Face (RF) | Mirror Polish, Matt, Sand-Blasted | Welding / Bolted Connection |

| Blind Flange | Carbon Steel (RST37.2, S235JR, C22.8, SS400, SF440) | ANSI Class 150 – 2500 lbs | DIN, EN, BS, JIS | DN15 – DN1200 (½" – 48") | Raised Face (RF) | Mirror Polish, Matt, Sand-Blasted | Welding / Bolted Connection |

Typical Applications

-

Oil & Gas Pipelines

-

Chemical & Petrochemical Plants

-

Water Treatment & Disposal

-

Power Plants & Electric Generation

-

Aerospace & Shipbuilding

-

HVAC & Fire Protection Systems

Quality & Logistics

-

Full quality control: chemical, mechanical, dimensional, hydraulic, X-ray inspection

-

Secure packaging: wooden boxes, pallets, cartons

-

Flexible trade terms: EXW, FOB, CFR, CIF

Company Introduction — Hebei Cangtie Industrial Co., Ltd

Hebei Cangtie Industrial Co., Ltd is a professional manufacturer and exporter of flanges and pipe fittings, including threaded flanges, socket weld flanges, slip-on flanges, weld neck flanges, elbows, reducers, and customized parts.

Our factory in Yanshan Economic Development Zone, Cangzhou City, Hebei Province, China is equipped with CNC lathes, forging presses, machining centers, and advanced inspection equipment to ensure accuracy and quality.

We have over 10 years of export experience, supplying products that meet ASME, ANSI, DIN, JIS, EN, and GB standards to clients worldwide in oil & gas, petrochemical, marine, water treatment, and construction sectors.

Contact Us

Contact Person: Hudson Liu

Mobile / WhatsApp: +86 157 3370 8805

Email: hudson@cangtiepipe.com

Website: https://ctflange.com/

Factory Address: Yanshan Economic Development Zone, Yanshan County, Cangzhou City, Hebei Province, China

Frequently Asked Questions (FAQ)

1. Are you a manufacturer or trading company?

We are a manufacturer with our own factory in Hebei, China, specializing in stainless steel and carbon steel flanges.

2. What materials do you offer?

-

Stainless Steel: 304, 304L, 316, 316L, 321, etc.

-

Carbon Steel: ASTM A105, ASTM A350 LF2, Q235, Q345, etc.

-

Alloy Steel: ASTM A182 F11, F22, F5, etc.

3. Which standards do your products comply with?

ASME B16.5, ANSI, ASTM, DIN, JIS, EN, GB — with third-party inspection available.

4. Do you offer OEM/ODM services?

Yes, we provide custom machining, surface treatment, packaging, and logo marking.

5. What is your MOQ?

MOQ is typically 1 piece for standard products; customized items may vary.

6. Do you provide samples?

Yes, free samples for standard sizes; buyer covers shipping.

7. What is your delivery time?

-

In-stock: 3–5 working days

-

Bulk/custom orders: 10–25 working days

8. How do you guarantee quality?

We conduct raw material inspection, dimensional verification, pressure/leak testing, and surface checks. Third-party inspection is available.