Product Description

Product Overview

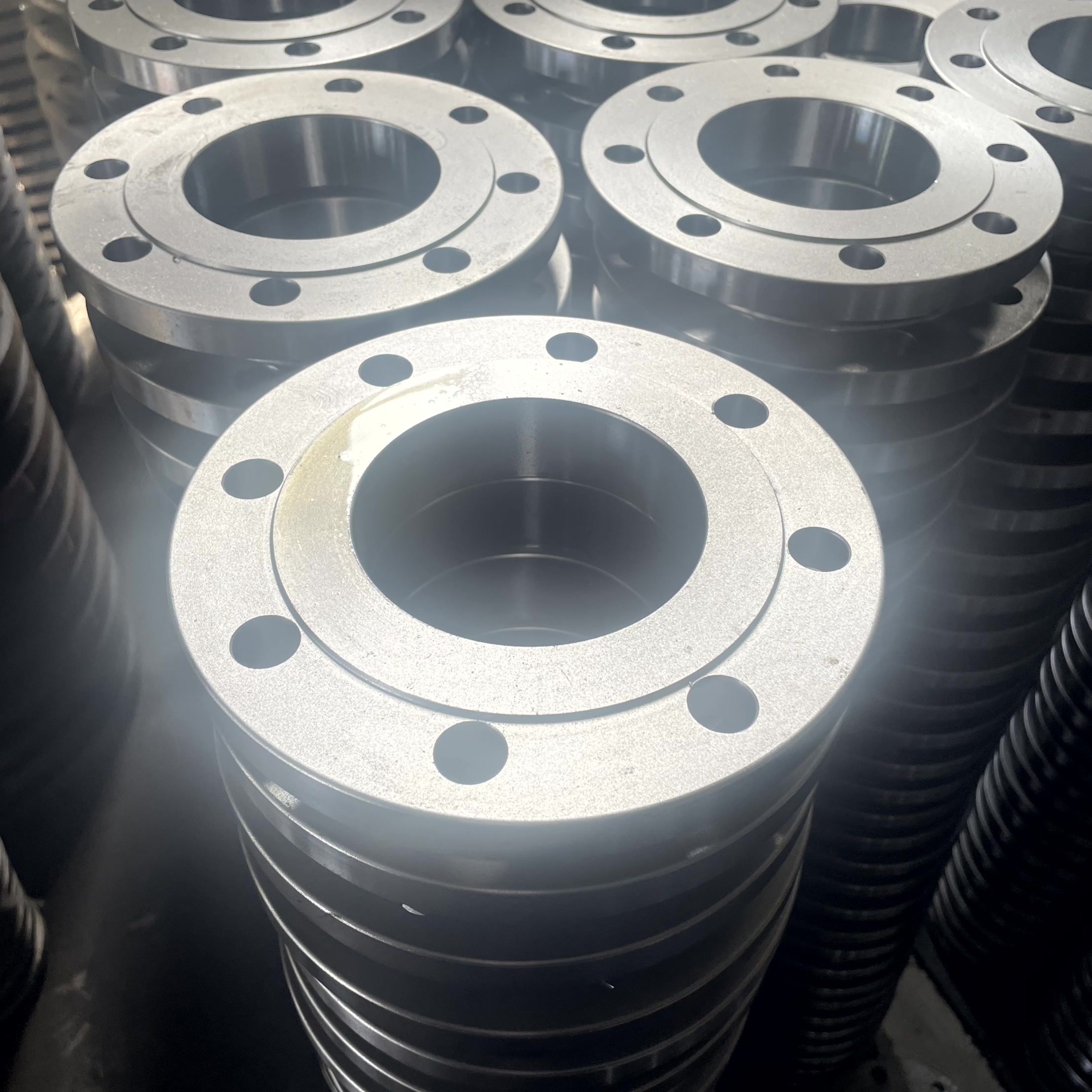

Forged Steel Socket Weld Flange – High-Strength, Leak-Proof Connection for Critical Piping Systems

Our Forged Steel Socket Weld Flange is engineered to meet the stringent ANSI/ASME B16.5 standards, providing a robust and reliable connection for small-bore, high-pressure piping systems. These flanges are designed to offer optimal performance, durability, and sealing integrity in demanding environments, ensuring a long service life even under extreme operating conditions.

Design and Features:

Socket Weld Connection: The unique socket weld design allows the pipe to be inserted into the recessed area of the flange and is securely fillet-welded around the outside. This ensures precise alignment, minimizes turbulence, and provides a smooth flow path for the fluid, significantly reducing the risk of leaks or flow disruption.

Surface Options: Our flanges are available with Raised Face (RF) and Ring Type Joint (RTJ) sealing surfaces, offering versatile sealing solutions depending on the application requirements. The RF provides a simple, effective seal for general use, while the RTJ is ideal for high-pressure and high-temperature conditions, ensuring superior sealing performance.

Material Options: We manufacture these flanges from high-quality forged carbon steel and stainless steel (304/316) to offer exceptional strength, corrosion resistance, and resistance to wear. These materials ensure that the flanges maintain their structural integrity and functionality in harsh environments such as high-temperature, high-pressure, or corrosive settings.

Applications:

Oil & Gas Industry: These flanges are widely used in upstream, midstream, and downstream operations, including in offshore rigs, pipelines, and refining processes, where high pressure and reliability are critical.

Petrochemical and Chemical Processing: The high corrosion resistance and strength of these flanges make them ideal for handling chemicals and other aggressive fluids in demanding processing environments.

Power Generation: Whether for nuclear, thermal, or renewable energy plants, the socket weld flange provides a durable and secure connection for piping systems handling high-pressure steam, hot water, and other fluids in power plants.

Water Treatment: Our flanges are also widely used in water and wastewater treatment plants, ensuring leak-proof connections in critical filtration and pumping systems.

Benefits:

Leak-Proof: The socket weld design, combined with high-quality materials, provides a reliable, leak-proof connection that reduces maintenance costs and ensures system integrity.

Durability and Corrosion Resistance: Manufactured from top-grade materials, these flanges offer excellent resistance to corrosion, especially in harsh and aggressive chemical environments, ensuring a long lifespan and reliable service.

High Pressure & Temperature Resistance: These flanges are designed to withstand high-pressure and high-temperature applications, making them suitable for some of the most demanding industrial applications.

Customization: Available in various sizes, pressure ratings, and materials, these flanges can be customized to meet the specific needs of any project, ensuring a perfect fit and optimal performance.

With the Forged Steel Socket Weld Flange, you can be assured of the highest quality, performance, and reliability, making it the ideal choice for your critical piping systems in industries like oil & gas, chemical processing, power generation, and water treatment.

Product Specifications

| Flange Type | Material | Standard / Grade | Size Range (Nominal Diameter) | Pressure Class |

|---|---|---|---|---|

| Socket Weld RF Flange | Carbon Steel, Stainless Steel (304, 304L, 316, 316L) | ASME B16.5 / ASTM A105 / A182 F304/F316 | DN15 – DN100 (½″ – 4″) | Class 150–2500 |

| Socket Weld RTJ Flange | Carbon Steel, Stainless Steel (304, 304L, 316, 316L) | ASME B16.5 / ASTM A105 / A182 F304L/F316L | DN15 – DN100 (½″ – 4″) | Class 300–2500 |

| Coated SW Flange | Carbon Steel (Galvanized, PTFE Coated) | ASME B16.5 / ASTM A105 | DN15 – DN100 (½″ – 4″) | Class 150–900 |

Sealing Face Options: RF (Raised Face), RTJ (Ring Type Joint)

Manufacturing Method: Forged & Machined

Surface Finish: Serrated concentric or spiral grooves

Company Introduction — Hebei Cangtie Industrial Co., Ltd

Hebei Cangtie Industrial Co., Ltd is a professional manufacturer and exporter of industrial flanges and pipe fittings, including socket weld flanges, slip-on flanges, weld neck flanges, blind flanges, elbows, reducers, and customized forged parts.

Our factory is located in Yanshan Economic Development Zone, Cangzhou City, Hebei Province, China, equipped with advanced CNC machining centers, forging presses, and strict inspection equipment to ensure product precision and reliability.

With over 10 years of export experience, our products comply with ASME, ANSI, DIN, JIS, EN, and GB standards, and are widely used in oil & gas, chemical, marine, water treatment, and construction industries across Europe, North America, Southeast Asia, and the Middle East.

Contact Us

Contact Person: Hudson Liu

Mobile / WhatsApp: +86 157 3370 8805

Email: hudson@cangtiepipe.com

Website: https://ctflange.com/

Factory Address: Yanshan Economic Development Zone, Yanshan County, Cangzhou City, Hebei Province, China

Frequently Asked Questions (FAQ)

1. Are you a manufacturer or trading company?

We are a manufacturer with our own factory in Hebei, China, specializing in forged steel flanges and pipe fittings.

2. What materials do you offer?

-

Carbon Steel: ASTM A105, ASTM A350 LF2, Q235, Q345, etc.

-

Stainless Steel: 304, 304L, 316, 316L, 321, etc.

3. Which standards do your products comply with?

ASME B16.5, ANSI, ASTM, DIN, JIS, EN, GB — with third-party inspection available.

4. Do you offer OEM/ODM services?

Yes, we provide custom machining, surface coating, marking, and packaging.

5. What is your MOQ?

MOQ is typically 1 piece for standard sizes; customized parts may vary.

6. Do you provide samples?

Yes, free samples for standard sizes; buyer pays shipping cost.

7. What is your delivery time?

-

In-stock: 3–5 working days

-

Bulk/custom orders: 10–25 working days

8. How do you ensure quality?

We conduct material inspection, dimensional checks, pressure testing, and surface finish inspection. Third-party inspection is available.