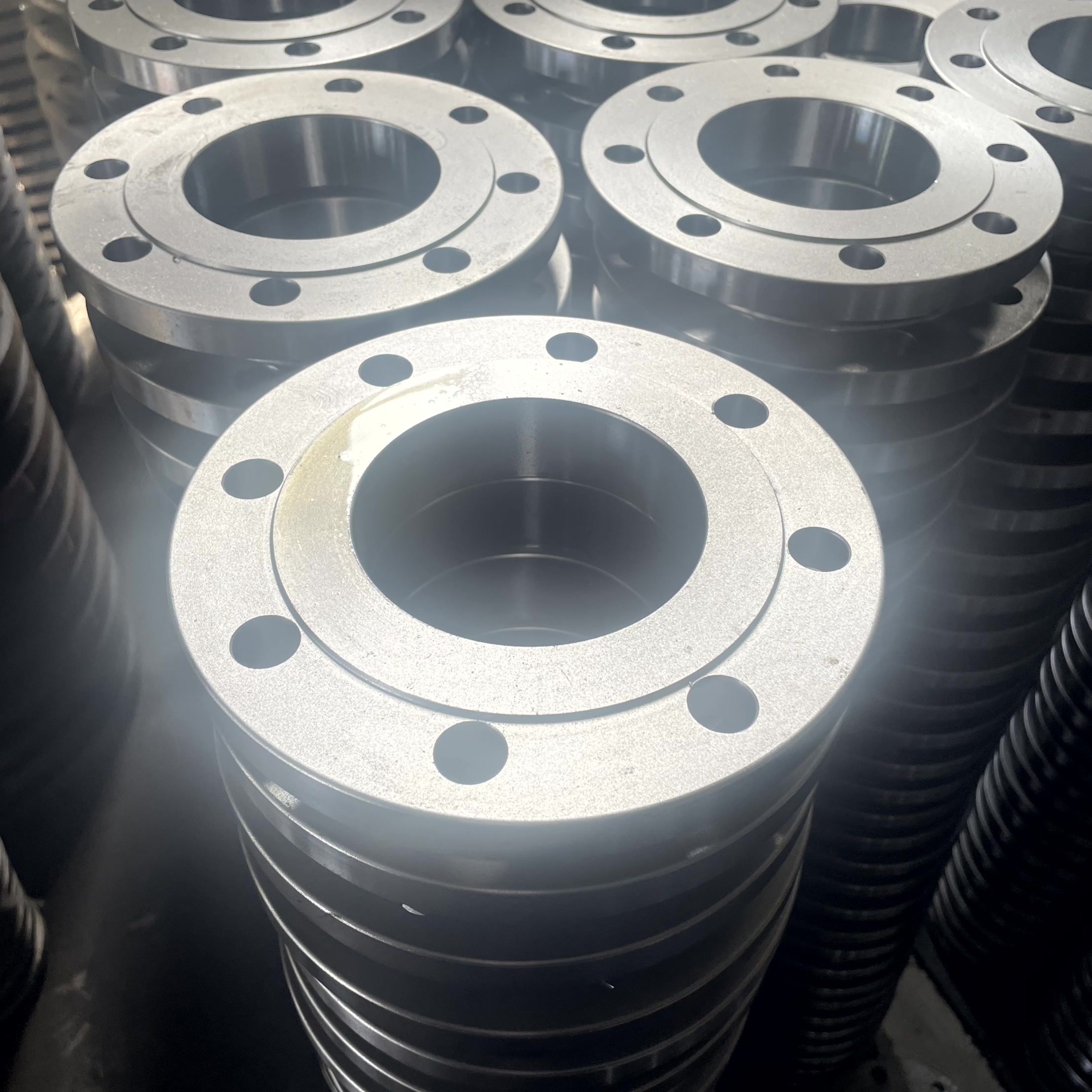

Specification: 6″ (NPS 6) | Class 150 | ASTM A105N | NACE MR0175/MR0103

This 6-inch Raised Face (RF) Blind Flange is engineered for high-integrity sealing of piping terminals and pressure vessel nozzles. Utilizing ASTM A105N (Normalized) forged carbon steel, this component is specifically processed to meet the hardness and microstructural requirements of NACE standards for service in sour gas (H2S) environments.

1. Technical Parameters & Compliance

| Parameter | Specification Details |

| Nominal Diameter | 6" (NPS 6 / DN150) |

| Material Grade | ASTM A105N (Normalized for improved grain structure) |

| Pressure Class | Class 150 (PN20) |

| Design Standard | ASME B16.5 |

| Sealing Face | Raised Face (RF) |

| Hardness Control | ≤ 22 HRC (As per NACE MR0175 / ISO 15156) |

| Gasket Surface | 125–250 AARH Serrated Finish |

2. Engineering & Metallurgy Notes

-

Normalization (ASTM A105N): Unlike standard A105, the "N" designation indicates the forging has undergone a controlled normalization heat treatment (heating above the transformation range followed by air cooling). This refines the grain structure, significantly improving impact toughness at lower temperatures and ensuring uniform mechanical properties.

-

NACE MR0175 Compliance: The material chemistry and hardness are strictly controlled to mitigate Sulfide Stress Cracking (SSC). This makes the flange suitable for upstream and downstream "sour" service where Hydrogen Sulfide is present.

-

RF Sealing Logic: The 0.06" (1.6mm) raised face concentrates bolt load onto a smaller gasket area, increasing the sealing pressure. The precision-machined concentric or spiral serrations prevent gasket "blow-out" by providing mechanical grip under internal fluid pressure.

3. Quality Assurance (QA) Protocols

To ensure adherence to critical infrastructure safety codes, each flange is subjected to:

-

PMI & Chemical Verification: Testing for Carbon Equivalent (CE) to ensure field weldability of mating components is not compromised by high hardenability.

-

Dimensional Inspection: Verified against ASME B16.5 Table 8, including thickness ($t$), bolt hole diameter, and Bolt Circle Diameter (BCD).

-

Hardness Testing: Conducted on the forging surface to confirm compliance with NACE HRC limits.

-

Non-Destructive Evaluation (NDE): Visual (VT) and Magnetic Particle (MT) inspection for surface-breaking discontinuities.

4. Application Environments

-

Sour Service Pipelines: Handling crude oil or natural gas with H2S content.

-

Refining & Petrochemical: High-pressure headers and heat exchanger bypasses.

-

Critical Utilities: High-pressure steam and hydrocarbon terminal points.

Procurement & Traceability

-

Manufacturer: Hebei Cangtie Industrial Co., Ltd (Cangzhou, China).

-

MTR Documentation: Comprehensive Material Test Reports provided per EN 10204 3.1, including heat treatment charts and chemical/mechanical test results.

-

Marking: Permanent stamping including Heat No., Size, Rating, Material Grade, and "NACE" designation.

Would you like me to provide the specific bolt torque values for this 6" Class 150 flange when used with a spiral wound gasket, or do you require the BCD (Bolt Circle Diameter) for your flange alignment check?

please contact us。