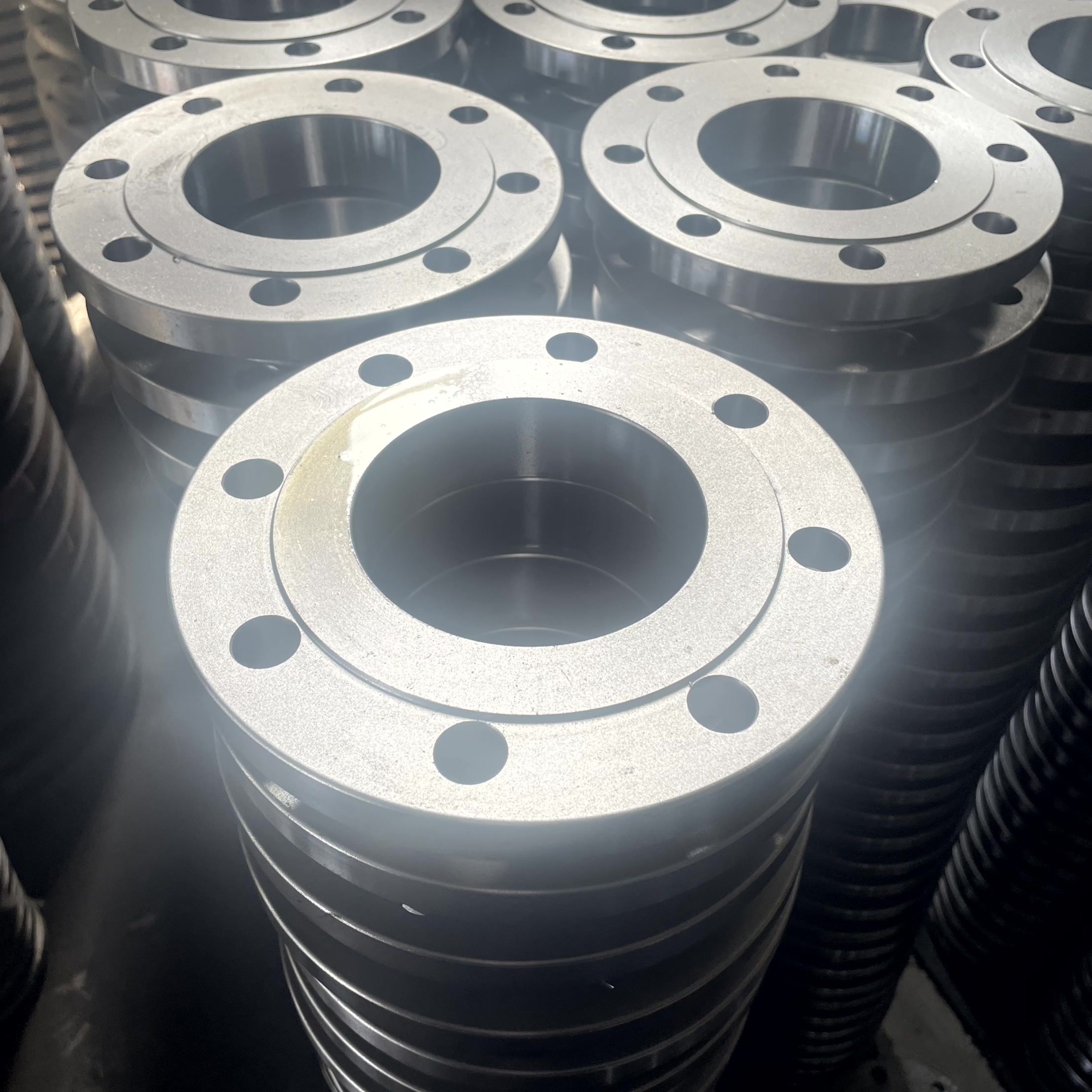

Technical Data Sheet: Forged Carbon Steel Blind Flange (FF)

Specification: 4″ (DN100) | Standard: ASME B16.5 | Pressure Class: Class 150/300/600

This 4-inch Carbon Steel Blind Flange is engineered for structural isolation and pressure containment at pipeline terminal points. Manufactured via closed-die forging, these components offer superior grain flow orientation and mechanical integrity compared to plate-cut alternatives, ensuring reliable performance under cyclic thermal and pressure loading.

1. Technical Specifications

| Parameter | Specification Data |

| Nominal Size | 4" (NPS 4 / DN100) |

| Material Grades | ASTM A105 (Standard), A350 LF2 (Low Temp), P250GH |

| Governing Standard | ASME B16.5 / ANSI B16.47 |

| Sealing Face | Flat Face (FF) |

| Surface Finish | Serrated Spiral or Concentric (125-250 AARH) |

| Pressure Ratings | Class 150 through Class 2500 (ANSI 500 support via custom spec) |

| Coating Options | Black Phosphating, Light Anti-Rust Oil, Cold/Hot-Dip Galvanized |

2. Engineering & Design Considerations

-

Flat Face (FF) Geometry: Specifically designed for mating with cast iron valves, pumps, or equipment flanges. The FF configuration eliminates the bending moment across the flange face during bolt torquing, preventing catastrophic fracture in low-strength or brittle mating components.

-

Forging Integrity: Our process ensures a high forging ratio, eliminating internal voids and porosity. Controlled normalization heat treatment is applied to refine the microstructure, enhancing notch toughness and ductility.

-

Sealing Surface Profile: Precision-machined serrations provide the necessary "bite" for the gasket material, increasing the friction factor and ensuring seal maintenance even during system pressure surges.

3. Quality Control & Compliance

Each unit undergoes a rigorous verification process to meet international safety codes:

-

Chemical Analysis: Verification of Carbon, Manganese, and Silicon levels to maintain a low Carbon Equivalent (CE) for optimal field weldability if secondary attachments are required.

-

Mechanical Testing: Destructive testing for Tensile Strength, Yield Point, and Elongation; Hardness testing (HB) performed on a per-heat basis.

-

Dimensional Tolerances: Strict adherence to ASME B16.5 requirements for Bolt Circle Diameter (BCD), flange thickness, and hole alignment.

-

Traceability: Every flange is hard-stamped with the Heat Number, Size, and Schedule, linked to a Certified Material Test Report (MTR) per EN 10204 3.1.

4. Industrial Applications

-

Potable Water & HVAC: Low-pressure utility headers and circulation pumps.

-

Petrochemical: Terminal points for non-corrosive hydrocarbon lines.

-

Infrastructure: Isolation points for pressure vessel inspection manways and handholes.

Procurement & Logistics

-

Manufacturer: Hebei Cangtie Industrial Co., Ltd (Cangzhou, China).

-

Documentation: Full MTR, Packing List, and Certificate of Origin provided.

-

Shipping: Sea-worthy export packaging (reinforced wooden crates/pallets) with VCI (Vapor Corrosion Inhibitor) lining.

Would you like me to provide the specific Bolt Circle Diameter (BCD) and bolt hole dimensions for the Class 150 or Class 300 configuration to assist with your piping layout?

please contact us