High-Performance Drainage Solutions for Municipal & Industrial Systems

Product Overview

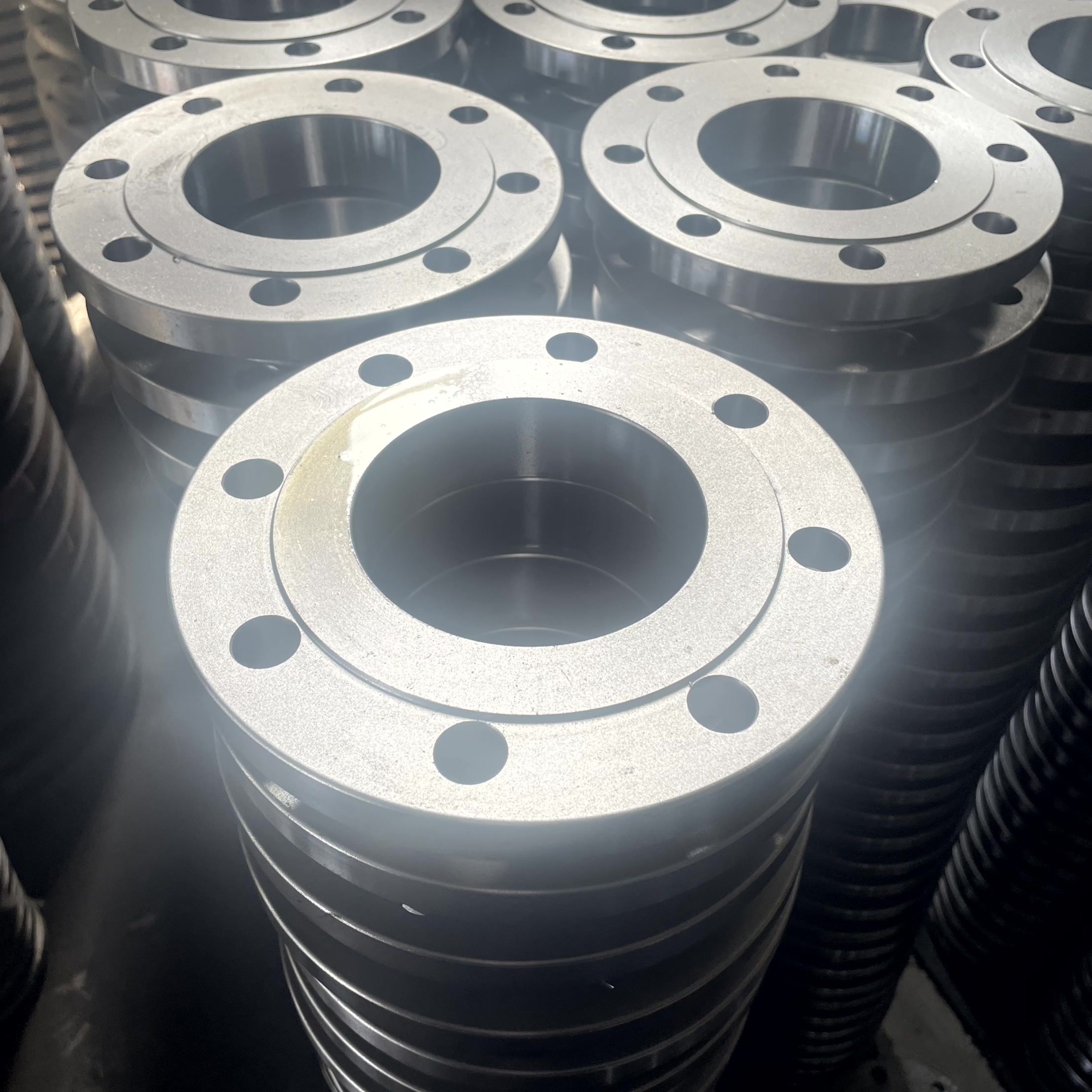

Our ASTM Carbon Steel Forged Flanges represent the gold standard in heavy-duty drainage connectivity. Engineered specifically for high-flow municipal and industrial wastewater environments, these flanges combine the precision of Threaded (NPT/BSPT) interfaces with the structural integrity of Socket/Butt Welding.

By utilizing premium ASTM A105 or A350 LF2 carbon steel and advanced forging techniques, we ensure a product that eliminates the risk of porosity and leakage, providing a service life that far exceeds cast alternatives in high-pressure or corrosive drainage scenarios.

Key Features & Advantages

-

Dual-Connection Integrity: Combines threaded convenience for rapid alignment with welding capability for permanent, leak-proof sealing.

-

Superior Grain Structure: Unlike cast flanges, our forged process aligns the grain flow of the steel, resulting in higher impact strength and resistance to fatigue.

-

Precision Machining: CNC-machined surfaces ensure a perfect gasket seat and smooth thread engagement, reducing installation time on-site.

-

Advanced Corrosion Protection: Available with Hot-Dip Galvanizing, Black Primer, or Electrostatic Epoxy Coating to withstand harsh underground and chemical environments.

-

Customization Ready: Full OEM/ODM support for non-standard thicknesses, special bolt-hole patterns, and specific coating requirements.

Technical Specifications

| Feature | Detailed Specification |

| Material Grades | ASTM A105 (Standard), A350 LF2 (Low Temp), Q235B, S235JR |

| Manufacturing Standard | ASME B16.5, ANSI B16.47, DIN, JIS B2220, EN1092-1 |

| Pressure Ratings | Class 150, 300, 600, 900, 1500, 2500; PN6 to PN100 |

| Size Range | ½″ (DN15) to 60″ (DN1500) — Full Bore Availability |

| Face Types | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Surface Treatment | Anti-rust Oil, Yellow/Black Paint, Galvanizing, Epoxy Coating |

Critical Applications

Our forged flanges are the preferred choice for mission-critical infrastructure:

-

Municipal Infrastructure: Sewage mains, stormwater runoff, and culvert systems.

-

Water Treatment: Sludge processing lines and desalination plant drainage.

-

Industrial Discharge: Chemical wastewater management and cooling water returns.

-

Energy & Mining: Tailings pipelines and power plant drainage systems.

Why Partner with Hebei Cangtie Industrial Co., Ltd?

1. Proven Expertise

Located in the heart of China’s piping hub (Cangzhou), we bring over 10 years of specialized manufacturing experience to your projects.

2. Rigorous Quality Control (QC)

We don't just "check" products; we validate them. Every batch undergoes:

-

Chemical Composition Analysis (PMI Testing)

-

Dimensional Inspection via High-Precision Calipers

-

Ultrasonic Testing (UT) for internal defects

-

Hydrostatic Pressure Testing

3. Global Supply Chain Readiness

With a 25-working-day lead time for bulk orders and a 1-piece MOQ for stock items, we support both large-scale infrastructure projects and urgent maintenance needs.

Contact Our Technical Sales Team

Ready for a quote or a technical consultation?

-

Contact Person: Hudson Liu

-

Mobile / WhatsApp: +86 157 3370 8805

-

Email: hudson@cangtiepipe.com

-

Official Website: https://www.ctflange.com/

-

Factory Location: Yanshan Economic Development Zone, Cangzhou City, Hebei Province, China.