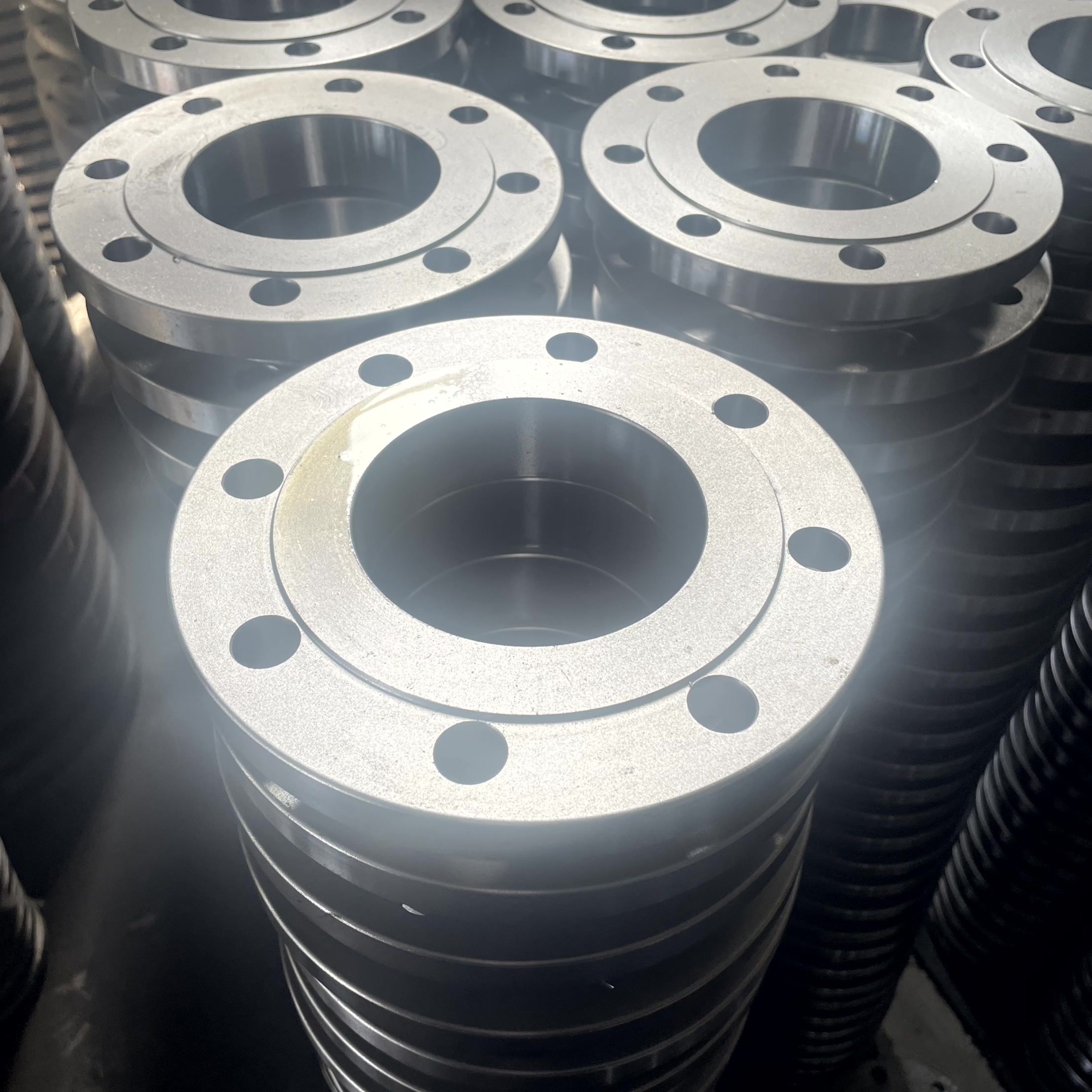

✨ High-Quality Product Description: DIN PN10/PN16 Threaded (Screwed) Flanges

Product Overview: The Weld-Free Connection Solution

Our DIN Threaded Flanges—available in both **Stainless Steel (SS304/316L) ** and **Carbon Steel (PN10/PN16) **—are engineered for industrial systems prioritizing speed and simplicity. Manufactured precisely to the DIN EN 1092-1 Standard, these screwed flanges feature precision-machined threaded bores that allow for quick, leak-proof installation without welding. This makes them the ultimate choice for high-maintenance applications where frequent assembly and disassembly are necessary.

We provide dual material options to meet any environmental demand:

-

Stainless Steel (SS304/316L): Offers superior corrosion resistance, ideal for sensitive media in the chemical, food, and beverage sectors.

-

Carbon Steel (PN10/PN16): A cost-effective, durable solution providing reliable mechanical strength for water treatment, HVAC, and general industrial pipelines.

🛠️ Technical Specifications & Engineering Advantages

| Feature | Detail Specification | Value Proposition |

| Flange Type | Threaded Flange (Screwed Flange), Flat Face (FF) or Raised Face (RF) available. | Zero Welding: Saves time, labor, and costs during installation and simplifies system maintenance. |

| Compliance | DIN EN 1092-1 (DIN Standard). | Guaranteed Fit: Ensures seamless compatibility with existing European standard pipelines and components. |

| Material Grades | Stainless Steel (304/316L); Carbon Steel (A105, Q235 - A350 LF2 available). | Optimal Material Selection: Choose based on fluid type, corrosion risk, and budget. |

| Pressure Rating | PN10 and PN16. | Reliable Medium Pressure: Perfectly rated for common distribution and utility piping systems. |

| Size Range | DN15 – DN200 (1/2" - 8"). | Standard Pipeline Coverage: Full availability in the most common small-to-medium bore sizes. |

🌍 Key Application Sectors

This flange's unique threaded design and PN10/PN16 rating make it indispensable in sectors demanding quick access and corrosion control:

-

Water and Wastewater Treatment: Where pipe segments require routine inspection or rapid replacement.

-

HVAC and Utility Piping: For non-critical lines where welding may be impractical or restricted.

-

Chemical/Petrochemical Processing: Utilizing the SS316L option for high resistance to aggressive chemicals.

-

Food, Beverage, and Brewing: Leveraging SS304 for sanitary and non-corrosive connections.

🏭 Partnership with Hebei Cangtie Industrial Co., Ltd

As a premier manufacturer and exporter of forged pipe fittings and flanges, Hebei Cangtie Industrial Co., Ltd provides reliable, standard-compliant products from our factory in Yanshan Economic Development Zone, China. Our 10+ years of experience ensure every DIN threaded flange meets rigorous quality controls, including CNC precision machining and dimensional verification. We are your trusted source for OEM/ODM and customized flange solutions.