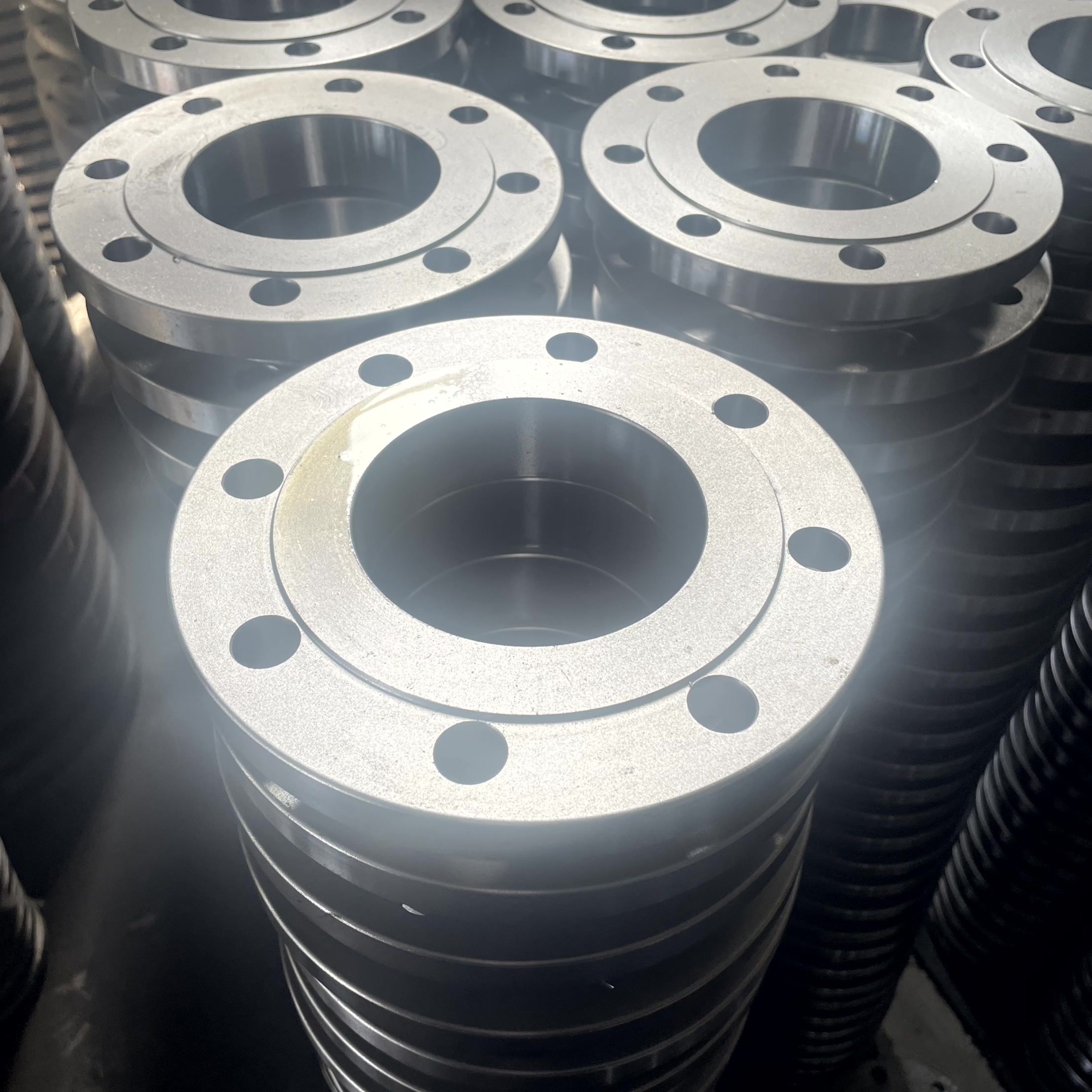

Customized Forged Stainless Steel Threaded Flanges

Precision Engineering | Multi-Standard Compliance | Bespoke Solutions

In complex industrial piping, "standard" isn't always enough. Our Customized Forged Stainless Steel Threaded Flanges bridge the gap between off-the-shelf components and specialized engineering requirements. We combine traditional forging craftsmanship with advanced CNC precision to deliver threaded solutions tailored to your exact system parameters.

1. The Power of Customization

We don't just sell flanges; we manufacture solutions. Our "Custom-First" approach allows you to specify:

-

Non-Standard Dimensions: Specialized Outer Diameters (OD), thickness, or hub heights to fit restricted spaces.

-

Unique Thread Profiles: Beyond standard NPT/BSP, we offer specialized threading (Metric, Trapezoidal, or custom pitches) to match proprietary equipment.

-

Specialized Facings: Custom Raised Face (RF) heights, Ring Type Joints (RTJ), or Tongue & Groove (T&G) configurations.

-

Bespoke Materials: High-performance alloys including Duplex 2205/2507, 904L, and Monel, in addition to standard 304/316L.

2. Multi-Standard Manufacturing Capability

Our facility is equipped to produce threaded flanges across all major global regulatory frameworks. Whether your project follows European, American, or Asian standards, we ensure 100% compliance:

| Standard Category | Specific Standards Covered |

| American Standards | ASME B16.5, ASME B16.47 (Series A/B), MSS SP-44 |

| European Standards | EN 1092-1, DIN 2565, DIN 2566, DIN 2567 |

| Japanese Standards | JIS B2220 (5K, 10K, 16K, 20K) |

| Marine Standards | DIN 86029, JIS F7805, CB/T Series |

3. Why Choose Our Precision Forged Fittings?

-

Superior Forging Integrity: Our flanges undergo a high-pressure forging process that creates a refined grain structure, offering significantly higher fatigue resistance than cast or plate-cut alternatives.

-

CNC Precision Threading: Utilizing high-precision CNC lathes, we ensure thread smoothness and tolerance accuracy, preventing galling and ensuring a leak-proof seal even in high-vibration environments.

-

Dual Certification: Most of our stainless products come standard as Dual Grade (e.g., 316/316L), optimizing both mechanical strength and corrosion resistance.

-

NACE & Harsh Environment Ready: Options for NACE MR0175/ISO 15156 compliance for sour gas or offshore applications.

4. Technical Capabilities At a Glance

-

Size Range: DN15 to DN600 (1/2" to 24") and custom large-diameter sizes.

-

Pressure Classes: PN6 to PN400 | Class 150 to Class 2500.

-

Surface Finishes: From 125-250 AARH (Standard) to mirror-polished or passivated finishes for pharmaceutical/food-grade use.

5. Quality Assurance & Traceability

Every customized flange is a critical component. We provide a comprehensive documentation package:

-

MTR (Material Test Report): Full chemical and mechanical analysis.

-

Dimensional Inspection Report: Verification of custom parameters.

-

Non-Destructive Testing (NDT): Ultrasonic or Liquid Penetrant testing upon request.

Challenge us with your drawings!

Do you have a specific technical drawing or a difficult-to-source flange specification? Send us your CAD files or PDF blueprints, and our engineering team will provide a feasibility analysis and a competitive quote within 24 hours. Would you like to see our Custom Project Gallery for inspiration?