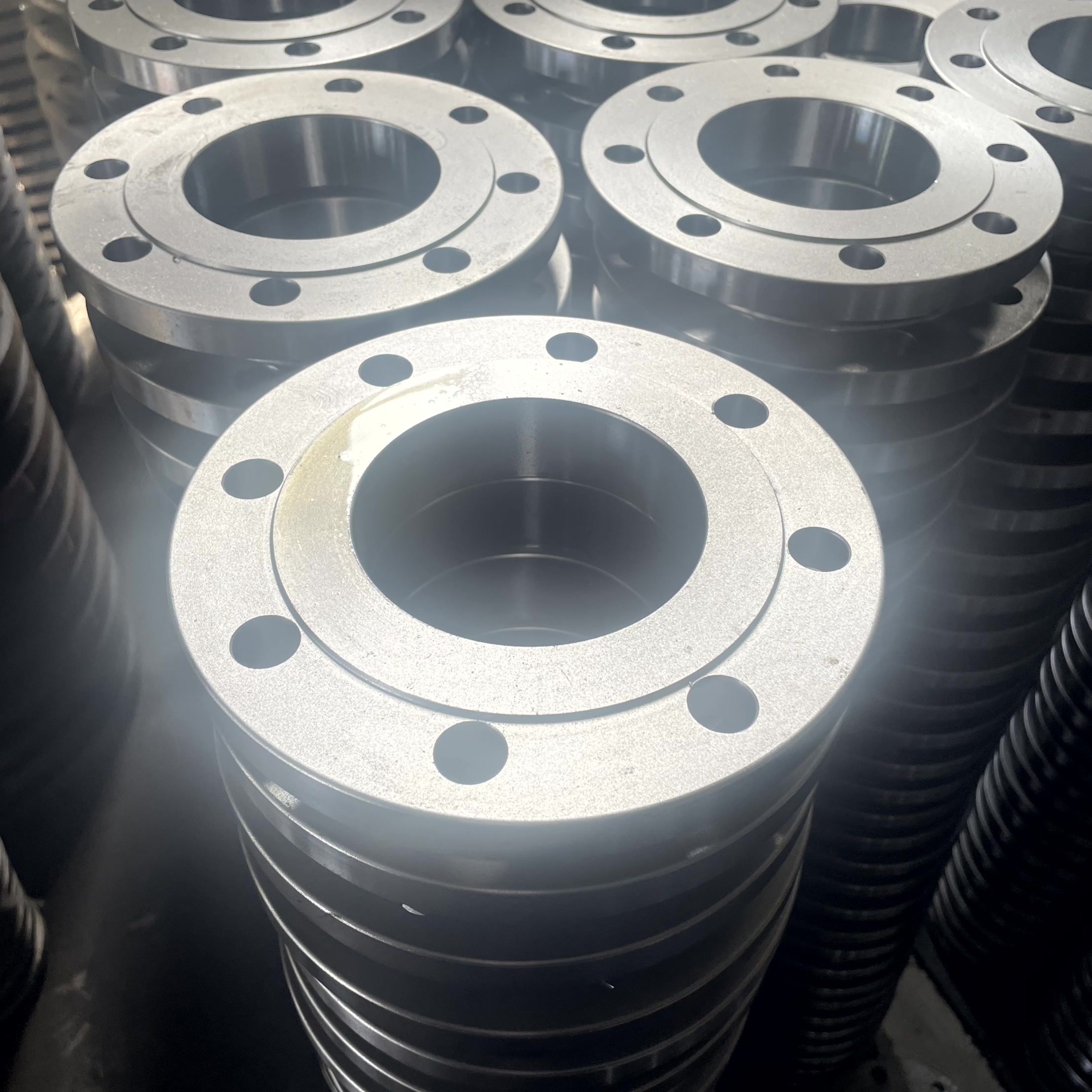

Product Overview

Our ODM Custom Carbon Steel Welding Threaded Flange is precision forged from high-grade carbon steel (ASTM A105 / A350 LF2) with optional stainless-steel or coating treatments. Combining a butt-weld body with an internal threaded bore, this flange offers welded strength where needed and a threaded connection for quick assembly/disassembly. Designed to meet ANSI/ASME and ISO-compatible dimensional tolerances, it’s ideal for oil, gas, water and industrial pipeline systems requiring reliable, leak-resistant joints and flexible OEM/ODM customization.

Product Specifications

| Item | Specification |

|---|---|

| Product Name | Welding Threaded Flange (Butt-Weld Body with Threaded Bore) |

| Main Materials | Carbon Steel (ASTM A105 / A350 LF2). Optional: Stainless Steel (304/316) and alloy steels. |

| Standards | ANSI / ASME B16.5; ISO compatible dimensions; other standards on request (ASTM, DIN, JIS). |

| Size Range | DN15 – DN200 (½″ – 8″). Larger sizes available upon request. |

| Pressure Class | Class 150 – 600 (custom ratings possible with engineering approval) |

| Manufacturing | Forged, heat treated, CNC machined (butt-weld forging + threaded bore) |

| Surface Finish | Black paint, primer, galvanized, epoxy coating, or per customer requirement |

| Connection Type | Butt-weld OD + internal threaded bore (screwed) |

Product Types (Table)

| No. | Product Type | Typical Materials | Typical Standards | Typical Applications |

|---|---|---|---|---|

| 1 | Screwed / Threaded Flange | Carbon Steel (ASTM A105), Stainless Steel (304/316) | ASME B16.5 / ANSI / ASTM | Piping that requires assembly without welding or frequent disassembly |

| 2 | Butt-Weld / Socket Weld Flange | Carbon Steel, Stainless Steel | ASME B16.5 / ASTM | High-strength, pressure-bearing pipe connections |

| 3 | Weld Neck Flange | Carbon Steel, Stainless Steel, Alloy Steel | ASME B16.5 / ANSI | High-pressure, long-distance pipelines and critical connections |

| 4 | Slip-On Flange | Carbon Steel, Stainless Steel | ASME B16.5 / ANSI | Low–medium pressure pipelines; economical installations |

| 5 | Blind Flange | Carbon Steel, Stainless Steel | ASME B16.5 / ANSI | Pipe end sealing, pressure testing, access ports |

| 6 | Forged Flange (Butt-Weld Forged) | Carbon Steel, Alloy Steel | ASTM / ASME | High-strength applications requiring forged parts |

| 7 | Lap Joint Flange | Carbon Steel, Stainless Steel | ASME B16.5 / ANSI | Frequent dismantling or flexible joint assemblies |

| 8 | Reducing / Spacer Flange (Reducing Flange) | Carbon Steel, Stainless Steel | ASME / ANSI | Connecting pipes of different diameters (transitions) |

| 9 | Ring Type Joint (RTJ) Flange | Alloy Steel, Stainless Steel | API / ASME | High pressure/high temperature sealing — oil & gas, refinery |

| 10 | Welded Body with Threaded Bore Flange | Carbon Steel, Stainless Steel | ASME / ASTM | Combined welding strength with removable threaded connection |

| 11 | Stainless Steel Flanges (304 / 316 etc.) | 304, 316, 316L | ASTM A182 / ASME B16.5 | Corrosive environments — chemical, food, pharma, marine |

| 12 | Alloy & Special Material Flanges (e.g., A182 F11/F22) | Alloy steels, high-temperature materials | ASTM A182 / ASME | High-temperature, high-pressure or specialty service (power plants, petrochemical) |

Key Features

-

Forged butt-weld body combined with precision internal threading for dual-function reliability.

-

Manufactured to ANSI/ASME and ISO-compatible tolerances for interchangeability.

-

Wide material options: carbon steel, stainless steel, and alloy steels.

-

Pressure classes from 150 up to 600; custom ratings available.

-

Multiple surface treatments available for enhanced corrosion resistance.

-

OEM/ODM customization: dimensions, marking, packaging, private labeling.

-

Quality control: raw material inspection, dimensional checks, pressure/leak tests; third-party inspection available.

Typical Applications

-

Oil & gas transmission and distribution pipelines

-

Petrochemical and refinery piping systems

-

Municipal & industrial water treatment and distribution

-

HVAC, fire protection and sprinkler systems

-

Offshore & shipbuilding (with appropriate materials/coatings)

-

Industrial plants requiring mixed welded/threaded connections

Company Introduction — Hebei Cangtie Industrial Co., Ltd

Hebei Cangtie Industrial Co., Ltd is a factory-based manufacturer and exporter of pipe fittings and flanges. Located in Yanshan Economic Development Zone, Cangzhou, Hebei Province, our facility includes forging, heat treatment and CNC machining lines. With over 10 years of experience, we supply products compliant with ASTM, ASME, DIN, JIS and ISO standards and offer flexible OEM/ODM services for global customers.

Contact Information

Contact Person: Hudson Liu

Mobile / WhatsApp: +86 157 3370 8805

Email: hudson@cangtiepipe.com

Website: https://ctflange.com/

Factory Address: Yanshan Economic Development Zone, Yanshan County, Cangzhou City, Hebei Province, China

FAQ (Short)

-

Are you a manufacturer? — Yes, we own a forging and machining factory in Hebei, China.

-

What materials do you offer? — Carbon steels (ASTM A105, A350 LF2), stainless steels (304/316/316L), alloy steels (A182 F11/F22) etc.

-

Which standards? — ASME B16.5, ANSI, ASTM, DIN, JIS, ISO — third-party inspection available.

-

MOQ & Samples? — Standard items: typically 1 pc; samples available (buyer pays shipping).

-

Lead time? — In-stock: 3–5 working days; bulk/custom: typically 10–25 working days.

-

Quality assurance? — Full inspection process (materials, dimensions, pressure tests); certificates on request.