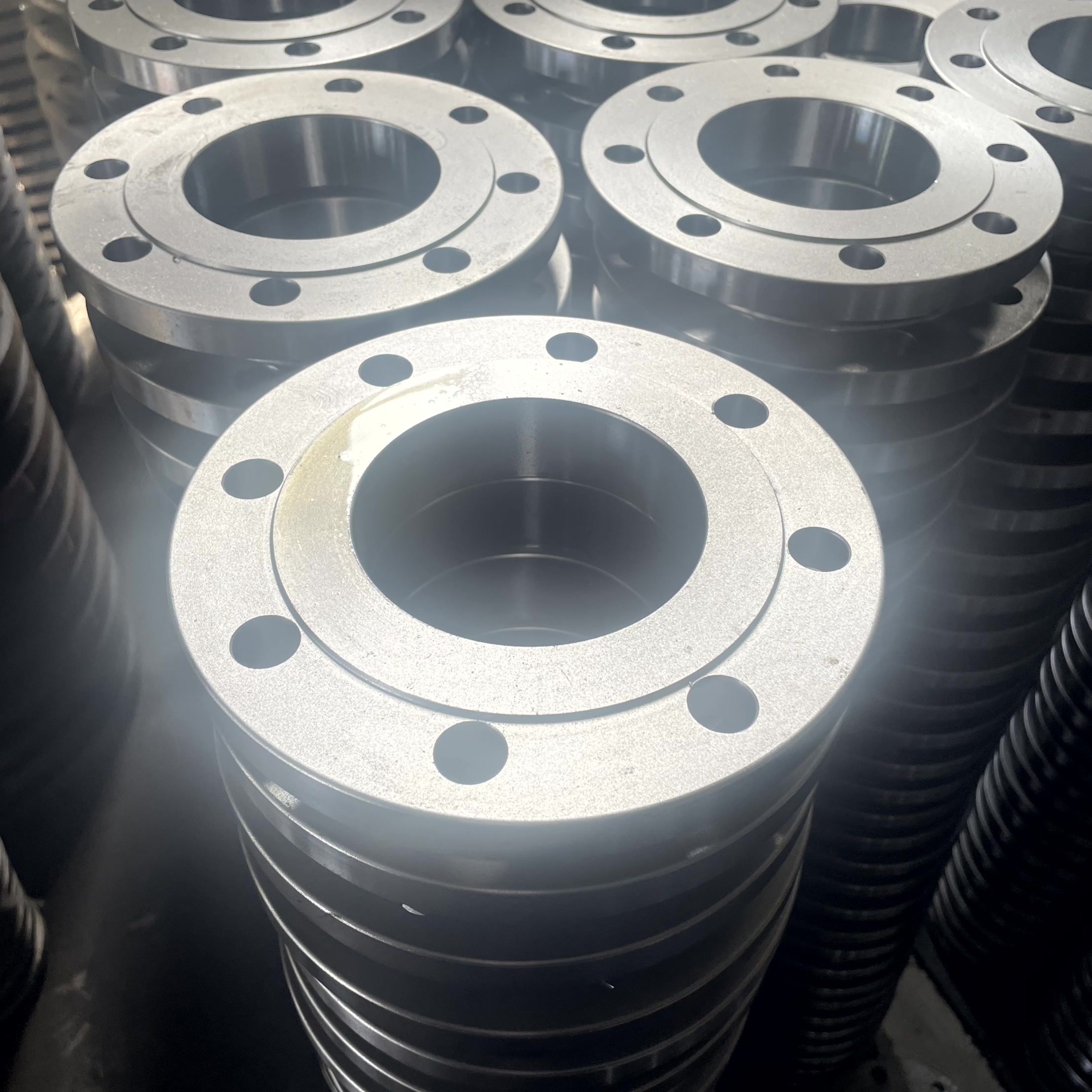

Product Overview

Precision-forged female (internal) threaded raised-face (RF) flange made from stainless steel grades 304, 316 and 316L. Designed to ASME/ANSI dimensions with Class 150 pressure rating and available with BSP (ISO 228) or NPT (ANSI B1.20.1) internal threads, this flange provides a compact, corrosion-resistant, easy-to-install connection for piping systems where welding is not desirable. Ideal for chemical, marine, water and sanitary applications that require reliable sealing and quick assembly/disassembly.

Product Specifications

| Item | Specification |

|---|---|

| Product Name | Female Threaded Raised Face Flange (RF) — Class 150 |

| Materials | Stainless Steel 304 / 316 / 316L (AISI) |

| Standards / Codes | ASME/ANSI B16.5 (dimensions & pressure class); thread standards: BSP (ISO 228), NPT (ANSI B1.20.1) |

| Connection Type | Internal (female) thread — BSP or NPT; Raised Face sealing surface |

| Size Range | DN15 – DN200 (½″ – 8″) — other sizes on request |

| Pressure Rating | Class 150 (150#) |

| Manufacturing | Forged / CNC machined / finish & passivation |

| Surface Finish | Smooth machined RF; options: polished, passivated, electropolished |

| Typical Coatings | Passivation, light polishing; PTFE / gasket recommendations for sealing |

| Inspection & Tests | Dimensional inspection, visual, material test certificate (MTC), pressure/leak test on request |

Thread & Sealing Details

-

BSP option: conforms to ISO 228 (parallel threads) — sealing achieved with gasket/washer or tapered seal depending on mating part.

-

NPT option: ANSI B1.20.1 (tapered thread) — often requires thread sealant or tape for leak-tight joint.

-

Raised Face (RF): standard RF face for use with standard gaskets (spiral wound, PTFE, compressed non-asbestos) to ensure reliable sealing at Class 150 pressures.

Key Features

-

Corrosion-resistant stainless steel construction (304/316/316L) for long service life.

-

Female (internal) threaded design — ideal where welding is impractical or prohibited.

-

Raised Face (RF) for improved gasket seating and leak-tight performance.

-

BSP and NPT thread options for international compatibility.

-

Forged and CNC machined for dimensional accuracy and interchangeability.

-

Surface treatments available (passivation, electropolish) for sanitary or marine environments.

-

Supplied with material certificates and inspection reports upon request.

Typical Applications

-

Chemical processing and corrosive fluid systems

-

Water treatment and distribution networks

-

Marine piping and offshore installations (with correct material selection)

-

HVAC systems and chilled water lines

-

Food, beverage and pharmaceutical piping (electropolished / 316L preferred)

-

Temporary connections, maintenance ports and instrumentation lines

Ordering Options & Customization

-

Choice of stainless grade: 304 / 316 / 316L

-

Thread type: BSP (ISO 228) or NPT (ANSI B1.20.1)

-

Size and pressure class per customer specification (other classes available on request)

-

Surface finish: passivated, polished, electropolished

-

Custom marking, private labeling and OEM/ODM packaging available

Company Brief — Hebei Cangtie Industrial Co., Ltd

We are a factory-based manufacturer specializing in flanges and pipe fittings, offering forged stainless-steel products with full quality control and export experience. Located in Yanshan Economic Development Zone, Cangzhou, Hebei Province, we supply global customers with MTC, inspection reports and OEM/ODM services.

Contact

Contact Person: Hudson Liu

WhatsApp / Mobile: +86 157 3370 8805

Email: hudson@cangtiepipe.com

Website: https://ctflange.com/

Short FAQ

Q: Do you supply 316L for food/pharma applications?

A: Yes — 316L and electropolishing/options for sanitary requirements are available.

Q: What thread standard should I choose, BSP or NPT?

A: Choose BSP for European / ISO-based systems (parallel threads), NPT for North American tapered thread systems. We can manufacture either.

Q: What gasket type is recommended for RF Class 150?

A: Commonly used: spiral-wound, compressed non-asbestos, or PTFE gaskets depending on media and temperature.